Understand various forming processes of metal materials (VII): Metal semi-solid forming

7、 Semi solid metal forming

Semi solid forming: the unique rheological and stirring properties of non dendritic semi-solid metals (SSM) are used to control the quality of castings.

Semi solid forming can be divided into rheological forming and thixotropic forming.

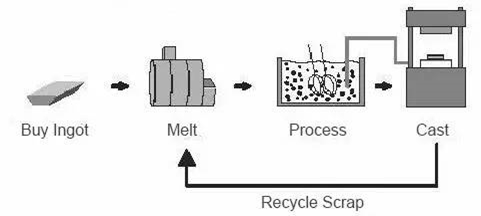

(1) Rheoforming

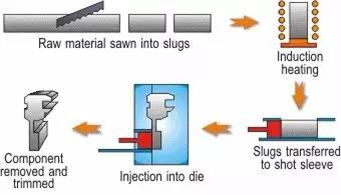

(2) Thixoforming

Technical features:

1. Reduce liquid forming defects and significantly improve quality and reliability;

2. The forming temperature is lower than the full liquid forming temperature, which greatly reduces the thermal shock to the mold;

3. It can produce alloys that cannot be produced by conventional liquid forming methods;

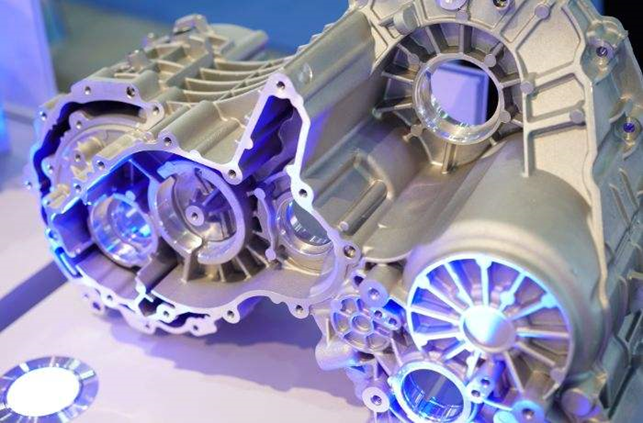

Application: at present, it has been successfully used in the manufacturing of master cylinder, steering system parts, rocker arm, engine piston, wheel hub, transmission system parts, fuel system parts and air conditioning parts, aviation, electronics and consumer goods.