Understand various forming processes of metal materials (V): Powder Metallurgy

5、 Powder metallurgy

Powder metallurgy: it refers to the process technology of making metal or using metal powder (or the mixture of metal powder and non-metallic powder) as raw material, forming and sintering, and manufacturing metal materials, composite materials and various types of products.

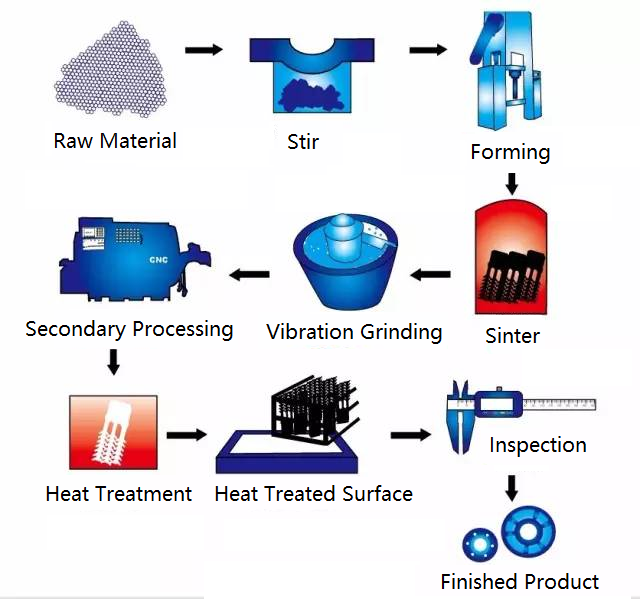

Basic process flow:

Process advantages:

1. Most refractory metals and their compounds, pseudoalloys and porous materials can only be manufactured by powder metallurgy.

2. Save metal and reduce product cost.

3. It will not pollute the materials, and it is possible to produce high-purity materials.

4. Powder metallurgy can ensure the correctness and uniformity of material composition.

5. Powder metallurgy is suitable for producing a large number of products with the same shape, which can greatly reduce the production cost.

Process disadvantages:

1. When there is no batch, the size of parts should be considered

2. The cost of mould is relatively higher than that of casting mould

Production scope of application: powder metallurgy technology can directly make porous, semi dense or fully dense materials and products, such as oil bearing, gear, cam, guide rod, cutting tool, etc.