Understand the past and present life of WEDM

1、 Problem summary:

With the progress of manufacturing industry, NC machining has gradually dominated the traditional machining, and the demand for employees’ understanding and understanding of special machining is also increasing. For NC technology, we can easily understand it as computer control principle, but we have less understanding of EDM technology. It is necessary to discuss NC machining equipment with you and understand the pillar of future industrial achievements.

Traditional machining has a long history. It has played a great role in human production technology and material civilization. However, with the progress of human science and technology, complex process production has seriously restricted the development of productivity. It was not until 1943 that lazarinkov of the former Soviet Union got rid of the traditional cutting methods. Use electric energy to cut metal. It generates a spark discharge between the negatively charged tool electrode and the positively charged workpiece to produce an instantaneous high temperature, which melts and gasifies the local metal and is etched away, so as to obtain the effect of “overcoming hardness with softness”.

2、 Classification and principle of electrical machining

According to the principle and energy function of EDM, it can be roughly divided into: EDM, electrochemical machining, electron beam machining, ion beam machining, plasma arc machining and so on. EDM, also known as electrical discharge machining (EDM) for short, is a machining method that continuously produces pulsed spark discharge between tool electrode and workpiece and corrodes metal by local instantaneous high temperature during discharge. Electrochemical machining is through the dissolution of electrolytic solution and metal ions. Electron beam processing is a kind of melting and gasification processing in the welding process. Ion beam processing is a kinetic energy processing of atomic impact by etching and implantation. Plasma arc machining is a kind of machining method which is melted by coating heat energy in the spraying process.

3、 Development and system structure of CNC machine tools

The emergence of CNC machine tools was successfully developed by Parsons company of the United States and the servo mechanism test Institute of Massachusetts Institute of technology in 1952. It was not until 1955 that the CNC system was put into practical stage. The development of CNC machine tools in China began with the three coordinate CNC machine tools developed by Tsinghua University in 1958. In 1966, the first transistor CNC system for linear arc interpolation was born, that is, the second generation CNC system, That is, the prototype of the routing control system of the current online cutting machine tool.

CNC numerical control system using microprocessor is the most used system at present. It is also the inevitable control means of modern computer network. As shown below:

Its working coordinate system is a right-hand Cartesian coordinate system. In programming, absolute coordinates and relative coordinates can be arbitrarily selected for chart program processing according to the marking method and accuracy requirements of drawing size.

4、 Classification of EDM

EDM is the most widely used machining method in the electrical machining industry, accounting for about 90% of the industry. According to the different ways of relative movement between tool electrode and workpiece, it can be roughly divided into six categories: EDM forming machining, wire cutting machining, EDM grinding machining, EDM synchronous conjugate rotation machining, EDM high-speed small hole machining, EDM surface strengthening and lettering machining. Among them, wire cutting accounts for 60% of EDM and EDM forming accounts for 30%. With the vigorous development of electrical processing technology, wire cutting has become the symbol of advanced technology.

5、 Principle of WEDM

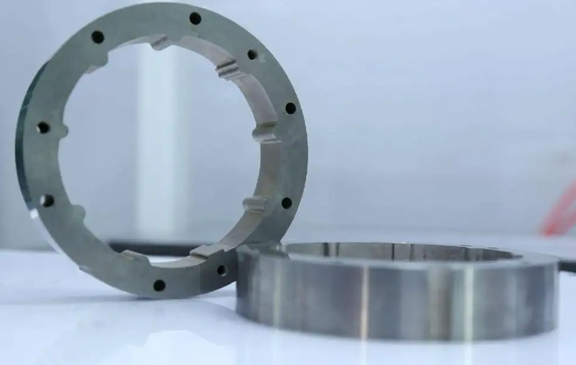

The basic principle of WEDM is to use the moving fine metal wire (copper wire or molybdenum wire) as the electrode to discharge the workpiece by pulse spark, which is fed through the computer control system. With a certain concentration of water-based emulsion for cooling and chip removal, the workpiece can be processed graphically.

6、 Classification and control mode of WEDM

① According to the control mode, it is divided into: imitation control, photoelectric tracking control, digital program control, microcomputer control, etc.

② According to the wire walking speed, it is divided into low-speed wire walking mode (commonly known as slow wire walking) and high-speed wire walking mode (commonly known as fast wire walking).

Modern electrical processing equipment has rarely relied on imitation control and photoelectric tracking control. Fast wire cutting mainly consists of desktop single board computer and cabinet industrial computer. The desktop single board computer is mainly controlled by 3B program. Individual also use 4B or 5B format. Cabinet industrial computer is the inevitable product of modern networking. The ISO code of international standardization procedure is adopted. CPU based control system mode. The control mode of slow wire cutting is mainly cabinet industrial computer. Most of them are fully intelligent operating systems. Domestic slow wire walking is generally semi-automatic control mode. Most of the imported machines are fully automatic operation. Deionized water is used as working fluid, and kerosene with good insulation performance is used only in special finishing.

0.06? 0.25mm molybdenum wire makes high-speed reciprocating motion, and its motion speed is 7? 10 m / s. The controllable machining accuracy is 0.005? About 0.015m. The electrode wire of slow wire cutting generally adopts 0.2mm copper wire for low-speed unidirectional movement. Its movement speed is less than 0.2 M / s. The controllable machining accuracy is 0.002? About 0.005mm. That is, 1 / 10 to 1 / 20 of a hair.

7、 Control medium

The control system of CNC wire cutting machine tool controls the processing according to people’s “command”. Therefore, the graphics to be processed by WEDM must be programmed with the “language” accepted by the WEDM control system. This “command” is the machining program. Programming is the most important technical core for WEDM. It is the main control means of whether the product size meets the standard or not and mold coordination. At present, the popular program formats mainly include 3B (individually expanded to 4B or 5b) format and ISO format. EIA (American Electronics Industry Association) format. China’s CNC wire cutting fast wire walking machine tools mainly adopt the unified five instruction 3B format.

In today’s IT era, information network has been integrated into the high-tech manufacturing industry. The traditional manual programming and paper tape control methods can no longer meet the needs of modern processing. The programming has been completed by computer. The current programming software mainly includes YH, CAXA, ycut, HGD, autop and zcad. In the direction of the development of automatic programming technology, the development of software is not only the simplification of graphic programming, but also some software is included in the mechatronics programming control system. Relying on scanning technology, supplemented by 4-axis linkage or 5-axis linkage control, combined with a number of technical parameter settings. The control system can produce ideal workpiece products.

8、 WEDM Process

From the technical point of view of EDM, the most important thing is its process technology and skills. Only when the process is reasonable, can high-quality workpieces be processed efficiently. Analyzing the drawing is the first step to ensure the quality of workpieces and the comprehensive technical indicators of workpieces, among which the processing route and correct clamping method are the most important. The processing operation mainly lies in the perpendicularity of the electrode wire, the adjustment of the electrical parameters of the pulse power supply, the control of variable frequency feed speed, etc., which are important symbols of surface roughness and machining accuracy.

9、 Concluding remarks

From the perspective of special machining, electrical machining is a result of the conversion of electric energy into thermal energy. From the perspective of NC machining, it is a combination of digital mode into mechanical mode, which has achieved the excellent position of NC electrical machining equipment in modern machining.