Structural design knowledge of sheet metal parts(III): Structural criteria for bending parts

1. Minimum bending radius of plate

When the material is bent, on the fillet area, the outer layer is stretched and the inner layer is compressed. When the material thickness is constant, the smaller the inner radius R is, the more serious the tension and compression of the material are; When the tensile stress of the outer fillet exceeds the ultimate strength of the material, cracks and fractures will occur. Therefore, too small bending fillet radius should be avoided in the structural design of bending parts. The minimum bending radius is specified for this purpose.

L bending radius refers to the inner radius of the bending part, and t is the wall thickness of the material.

L t is the wall thickness of the material, M is the annealed state, y is the hard state and Y2 is 1 / 2 of the hard state.

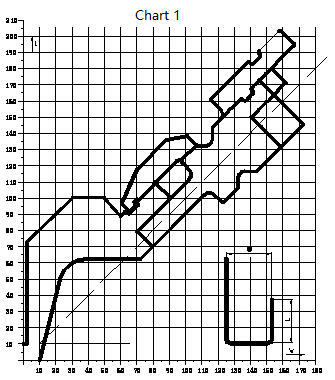

For the closed edge bending parts as shown in the figure below, the maximum edge bending height h shall not exceed 40mm. If it needs to be greater than 40mm, it can be used only after verification.

2. Minimum straight edge height of bending

The straight edge height of bending should not be too small, otherwise it is not easy to form enough bending moment, and it is difficult to obtain parts with accurate shape. Its value H ≥ R + 2T.

① Minimum straight edge height requirements in general

The straight edge height of the bending part shall not be too small, and the minimum height shall be in accordance with the requirements of the drawing: H > 2T.