Solutions to lathe machining problems (I): Vibration vibration cutter

The vibration and vibration of the tool in lathe machining cause chattering lines on the surface of the workpiece, and the rework rate and scrap rate are high. The vibration of machine tool is generally caused by the insufficient rigidity of any or more of the three systems of machine tool, workpiece and tool. Let’s first talk about the aspects that need to be investigated when vibration and vibration occur.

A. Troubleshooting points for workpieces:

(1) . cylindrical turning of slender shafts; In general, the distance between the cutting point and the clamping point is easy to vibrate if the length diameter ratio exceeds 3. You can consider changing the lower process.

(2) Outer circle turning of thin-walled parts.

(3) Turning of box parts (such as sheet metal welded structural parts).

(4) Cutting of superhard materials.

B. Tool reason:

(1) Use the forming blade for forming turning;

(2) The angle of the tool, especially the main deflection angle, back angle, front angle, etc;

(3) The sharpness of the blade;

(4) Whether the arc radius of the tool tip is too large;

(5) Whether the cutting parameters are appropriate.

C. Machine tool reason:

(1) . the extension of movable top is too long

(2) The bearing has been damaged and cutting continues

1、 First, eliminate the problem of the tool:

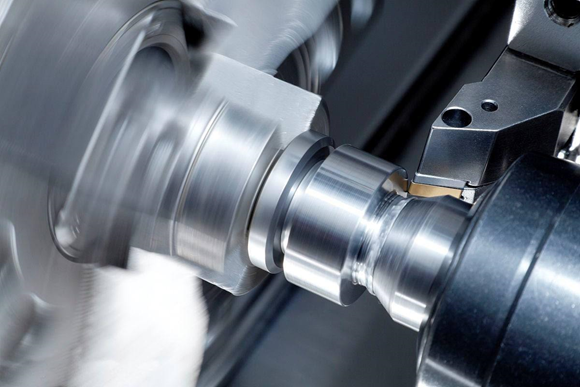

First check the rigidity of the turning tool itself and whether it is not clamped? Is the extension too long? Is the gasket uneven? Check whether the turning tool (boring tool) is worn? Is the tip fillet or polishing edge too wide? Is the rear angle of turning tool too small? See if you are using a 90 degree knife or a 45 degree knife. Try changing it. In addition, if the feed rate is too small, it may also be an inducement to produce chattering lines, which can be slightly adjusted and increased. You can adjust the rotating speed, single tool cutting depth and feed rate, and try to eliminate the resonance point.

2、 Check the causes of machine tool and clamping position:

(1) Find out whether your movable center extends too long and whether the bearing is good. There is a combination of flat rolling bearings. If you doubt it, you can replace it with a dead center. Pay attention to the butter lubrication of the center hole.

(2) Find out the clamping condition of the tailstock top. Under the clamping condition, whether the left and right sides, up and down sides are not concentric with the machine tool spindle.

(3) Tighten the large, medium and small tugs, especially the middle tug.

(4) If you can’t check the tailstock of the machine tool for the time being (points 1 and 2 require some fitter Foundation), you can try to walk the knife from the clamping end to the tail. Anti car can suck the force at the end of the tail.

(5) If there is still a situation in step 4, it is necessary to check the main shaft. Of course, if it is three grabs, it is also necessary to check whether the spiral groove is damaged. The fourth grasp is manually self-supporting, so there is no need to check.

3、 Countermeasures for restraining vibration of knife:

If your main bearing bush is really tight in place, the workpiece is not a thin-walled hollow part or the suspension is too long, and the chuck clamping is no problem. Adopt some other countermeasures to restrain the vibration of the knife. According to the principle of vibration knife obtained from the research, there are some specific and practical methods applied to the processing site at present:

(1) Reduce the working weight of the part causing vibration. The smaller the inertia, the better.

(2) . fix or clamp the place with the largest vibration, such as center frame, work holder, etc.

(3) Improve the rigidity of the processing system, such as using a tool handle with high elastic coefficient or using a special seismic force added with dynamic damper to absorb impact energy.

(4) Work hard in the direction of blade and work rotation.

(5) Change the shape and feed angle of the tool. The smaller the nose radius of the tool, the better, so as to reduce the cutting resistance. The side rake angle must be positive to make the cutting direction more vertical. The back rake angle is better to be positive, but the chip removal ability is relatively poor. Therefore, the grooving knife can be selected to make the angle negative, but still maintain the positive cutting effect.