Sheet metal processing technology – sheet metal process flow

With the updating and iterative development of the manufacturing industry, the sheet metal industry has also developed rapidly. Now sheet metal involves all walks of life. For any sheet metal part, it has a certain processing process, which is the so-called sheet metal processing process

Sheet metal processing process:

Blanking: digital blanking, laser cutting, plate shearing machine

Forming – bending, stretching, punching: bending machine, punch, etc

Other processing: press riveting, tapping, etc

Welding: how sheet metal is joined

Surface treatment: powder spraying, electroplating, wire drawing, silk screen, etc

First, count blanking

After the drawings are received, the blanking methods of sheet metal mainly include digital blanking, laser cutting, plate shearing machine, mold blanking, etc. CNC is currently the common method. Laser cutting is mostly used in the proofing stage (also can process stainless steel sheet metal parts), with high processing costs, and mold blanking is mostly used for mass processing.

Second: deburring of sheet metal process flow

After the workpiece is blanking, the corners, burrs, sticking points and peeling shall be trimmed as necessary. At the tool contact, the flat file shall be used for trimming. For the workpiece with large burrs, the angle grinder shall be used for trimming.

Third: sheet metal process flow, riveting, tapping and spot welding

After blanking, enter the next process, and different workpieces enter the corresponding process according to the processing requirements.

There are bending, riveting, flanging, tapping, spot welding, and segment difference. Sometimes, after bending for one or two times, the nuts or studs should be pressed well. Where there are mold bumps and segment differences, processing should be considered first,

In order to avoid interference in other processes after processing, the required processing cannot be completed. If there is a hook on the upper cover or lower shell, if there is no butt welding after bending, it shall be processed before bending.

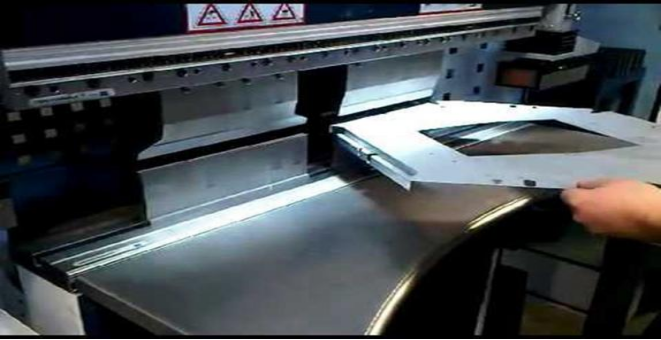

Fourth: sheet metal process flow, sheet metal bending

When bending, it is necessary to first determine the tool and groove for bending according to the size on the drawing and the material thickness. The key to selecting the upper mold is to avoid the deformation caused by the collision between the product and the tool. The selection of the lower mold is determined according to the thickness of the plate.

The second is to determine the sequence of bending. The general rule of bending is that the bending is from inside to outside, from small to large, and from special to ordinary. For the work-piece with dead edge to be pressed, first bend the work-piece to 30 ° – 40 °, and then use the leveling die to press the work-piece to death.

During riveting, the same and different moulds shall be selected according to the height of the stud, and then the pressure of the press shall be adjusted to ensure that the stud is flush with the surface of the workpiece, so as to avoid that the stud is not pressed firmly or pressed out beyond the surface of the workpiece, causing the workpiece to be scrapped.

Fifth: sheet metal process flow, sheet metal welding

Welding includes argon arc welding, spot welding, carbon dioxide shielded welding, manual arc welding, etc. For spot welding, the position of workpiece welding shall be considered first, and positioning tooling shall be considered during mass production to ensure accurate spot welding position.

In order to weld firmly, punch a bump on the workpiece to be welded, which can make the bump contact with the flat plate evenly before power on welding, so as to ensure that the heating of each point is consistent, and the welding position can also be determined

Similarly, to weld, adjust the preloading time, holding time, holding time and rest time to ensure that the workpiece can be spot welded firmly. After spot welding, there will be welding scar on the workpiece surface,

The flat mill shall be used for processing. The sub arc welding is mainly used when two workpieces are large and need to be connected together, or the corners of one workpiece shall be treated to achieve the flatness and smoothness of the workpiece surface.

The heat generated during sub arc welding is easy to deform the workpiece. After welding, it needs to be treated with a grinder and a flat grinder, especially in terms of edges and corners.

Sixth: sheet metal process flow and surface treatment

The workpiece shall be subject to surface treatment after bending, riveting and other processes are completed. The treatment methods of different plate surfaces are different. After cold plate processing, surface electroplating is generally carried out. After electroplating, no spraying treatment is carried out. Phosphating treatment is adopted, and spraying treatment is carried out after phosphating treatment. The surface of electroplating plate shall be cleaned, degreased and then sprayed.

The stainless steel plate can be brushed before bending without spraying, and roughening treatment shall be carried out if spraying is required;

Aluminum plates are generally treated by oxidation, and different oxidation background colors are selected according to different colors of spraying. Black and natural color oxidation are commonly used;

Aluminum plates to be sprayed shall be sprayed after chromate oxidation treatment. The surface pre-treatment can clean the surface, significantly improve the adhesion of the film, and can double the corrosion resistance of the film.