Problems needing attention in the process of ultra mirror polishing

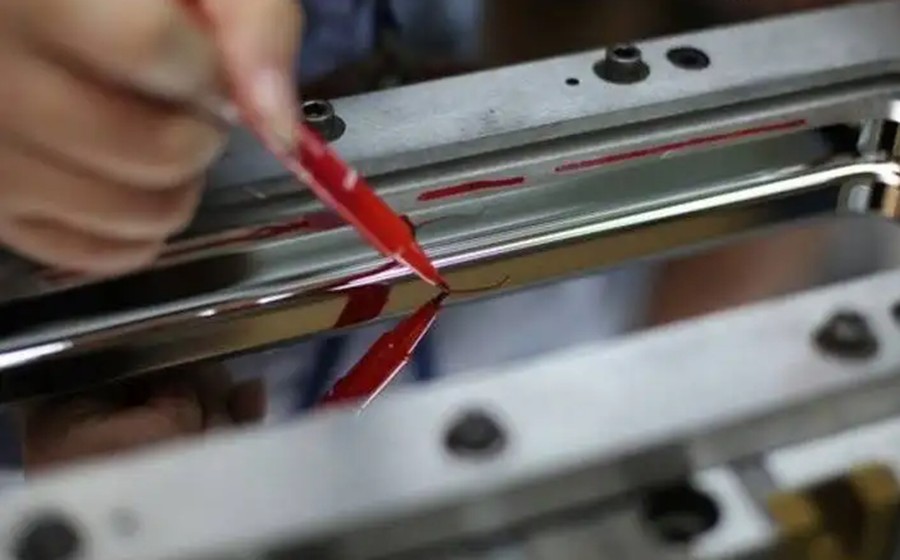

The most important point in ultra mirror polishing is the size of the polishing. The distance from the whetstone to the mirror polishing is the most basic principle (ideally # 1500 whetstone starts to grind). Before the next operation, the mold must be thoroughly cleaned to achieve good results. Be very careful not to make repeated modifications (repeated modifications will affect the quality).

The deadline for delivery, time pressure, excessive fatigue, and reduced concentration are all factors that can easily affect the work, which should be paid attention to. Experts pointed out that polishing operation is a time-consuming and expensive process, and following certain rules can reduce the cost of polishing operation. Every step of polishing must be kept clean, which is the most important.

1. Polishing must be carried out in a clean and dust-free room. Because hard dust particles will contaminate the abrasive material and damage the nearly completed mold surface.

2. Use only one grade of polishing diamond paste for each polishing tool and store it in a dust-proof or sealed container.

3. When it is necessary to change a finer sand grade, both hands and the workpiece must be cleaned.

4. At the beginning of polishing, corners, corners, fillets and other places that are difficult to polish should be treated first.

5. When processing sharp corners and corners, special care shall be taken not to form rounded corners or rounded edges. Hard polishing tools shall be used as far as possible for mold grinding and oilstone grinding.