NC milling machine tools also need physical examination to teach you how to diagnose

Machine tool structural parts

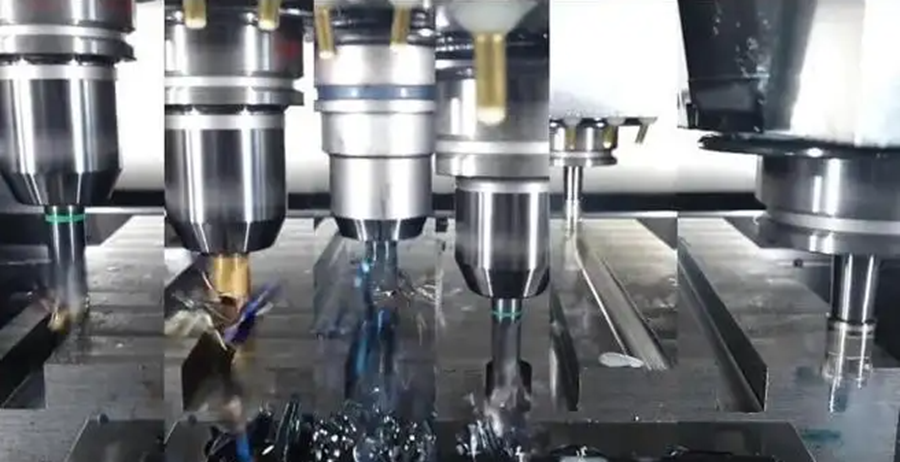

The spindle is an original electric spindle imported from Italy. 2. Japanese servo motor and high-precision linear guide rail are used. 3. Casting table. 4. High power dust collector

Now, CNC milling machines have a wide range of uses in our lives, especially in industry. However, it has always been a difficult problem to detect and record the tool wear of CNC milling machines. Now, we invite relevant experts to introduce how to record the tool wear of CNC milling machines.

In the past, people mainly used the magnifying glass integrated with the measuring ruler to check the universal milling machine. Although it can improve the flexibility of measurement, the difference of operators will lead to inconsistent measurement results. Similar results can show another tested system: on the one hand, although the fixed measuring system has better economy, its portable function is poor; On the other hand, the measurement accuracy of the simple mobile measurement system is low, the imaging quality is poor, and the measurement depth is insufficient. Now the universal milling machine mainly uses graphics to show the production efficiency of the processing tools, and the process that the wear scratch depth (VB) gradually deepens with the increase of the service life.

The processing process can be optimized by putting the whole system into a portable container and providing necessary backup batteries, chargers or cleaning appliances. Structure of measurement system: A digital camera equipped with a magnetic tripod is placed directly in front of the rotary table milling cutter of the milling machine. Shanghai Weihong Electronics said: “The high quality of the picture, the convenient manipulation of the measurement system and the evaluation software are our advantages. Moreover, we repeatedly asked users and tool manufacturers during the measurement process whether they need to provide them with an integrated measurement system package with software.”

So far, technologists from aviation industry, tool manufacturing industry and scientific research instrument industry have started to apply this system in cutting. When checking and optimizing the measuring system, it is compact and practical:

1) Measuring software easy for users to manipulate: abrascan, the evaluation software included in the wear measurement package, can measure the interval (D), angle (A) and radius. Click the “Interval” icon to display the relevant dimensions in millimeters. More intervals and angle measurements can also be displayed in separate pictures. Right click to copy the relevant data and save it as an Excel table file. This can greatly simplify the formation process of wear scratch width. Other auxiliary functions, such as brightness, contrast and grayscale, are also available. Because the universal milling machine system is based on Office software, users can quickly use it without taking additional training.

2) Output measurement value: store the measurement value in the table calculation software of X5036A vertical milling machine to form a natural wear process. The abrascan wear measurement system can identify extremely small wear traces and measure them. Therefore, the tool can be optimized. Abrascan’s image can show that the horizontal axis of the formation process of wear is the chip spacing of the tool, in meters; The longitudinal axis is the width of abrasion scratch VB, in mm; The three curves are tool A, B and C.

3) Rotary table: wear scratch width VB=0.136mm: the measurement process is as follows: fix the digital camera on the magnetic tripod, and the magnetic tripod can also be used to directly measure the length of the milling machine without removing the tool from the bracket or the spindle. X6132A horizontal milling machine is equipped with a display screen that can rotate freely, and can be photographed at any position. Therefore, users only need to turn on the digital camera to shoot at any time. Of course, those interested in photography can also fine tune according to different occasions. The rotor pump can transfer the stored pictures to the notebook computer through USB data line and use software for evaluation.

4) The measurement process is very simple: the first user of the system was encouraged: “All the adjustment parameters have been stored on the camera – clear and sharp photos can be taken five minutes after opening the package.

You must have a good understanding of the record of tool wear of CNC milling machine through the above introduction of experts of Shanghai Weihong Electronics! I hope that the above knowledge can help you improve your knowledge of relevant aspects.

development direction

Based on the obvious advantages of foam model CNC machining required for solid casting, such as uniform and accurate margin and good overall appearance of the mold, Xinghui CNC is the earliest and most mature enterprise producing model CNC machine tools in China. Jinan Xinghui CNC participated in drafting and revising part of the articles of association of the technical standards of China’s solid casting industry, and is a leading enterprise in China’s model CNC machine tool industry. Xinghui CNC produces model CNC machine tools according to the idea of metal cutting machine tools. The important processing parts of the machine tools are subject to annealing and other heat treatment processes. After the processing is completed, coordinate measurement is carried out to ensure the accuracy of parts. The whole process sequencing processing of foam will be the direction of future development. Of course, there are many technical problems in this field that need further exploration and research.

Development goals

In 2012, the “12th Five Year Plan” development goal of the machine tool industry has been clarified, and high-end CNC machine tools will become the focus of future development. According to the development goals, from 2012 to 2016, China will move steadily towards a powerful machine tool country, and the industrial structure will be significantly improved. 80% of the varieties of domestic machine tools will meet the needs of domestic engineering projects, and the market share of CNC machine tools will reach more than 70%.