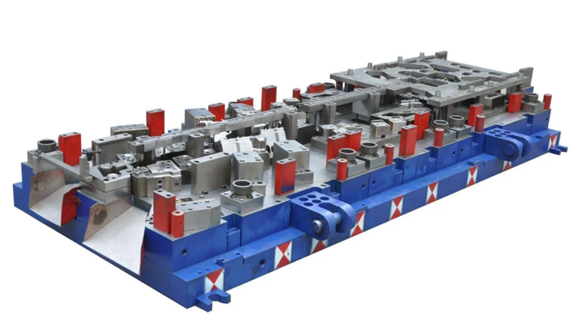

Modular design of punching and trimming components of progressive die for automotive structural parts

Automobile structural parts refer to the load-bearing parts or stress-bearing parts in the automobile, which are closely related to automobile safety. In the automobile body, many structural parts are installed on the nodes of the body structure and connected with other structural parts to form a high-strength frame with deformation resistance. Because of the complex structure and high precision requirements of such parts, multi station progressive die is usually used for production. Although the progressive die for automobile structural parts has many advantages, such as high production efficiency, saving material cost and good product accuracy, the combination of the structural characteristics of the progressive die and the complex forming process of automobile structural parts makes the structure of such die complex and the size large, which greatly increases the difficulty of die design and manufacturing. Of course, it takes 3 months or even longer from the design to the delivery of a progressive die for a pair of automotive structural parts, and the designer needs to accumulate rich design experience in practice to be competent. The analysis and calculation of the whole design process are complex and need to be revised repeatedly. The design work efficiency is low and cannot meet the requirements of the market for product upgrading.

With the development of domestic automobile market, enterprises are eager to improve the efficiency and quality of mold design. At present, some die CAD systems have been used to assist the progressive die design. However, from the use effect, these systems have the problems of low integration, specialization and customization, which are difficult to meet the requirements of progressive die design for automotive structural parts. The reason is that the structure of automotive structural parts is complex, and the corresponding progressive die usually includes punching, trimming, bending, forming and other multi-channel stations. Each work station is completed by working components composed of punch, female mold, standard parts, plate inserts and other parts. However, the existing mold design system usually focuses on the design of individual parts. By providing a series of parts design tool sets, users can use them together to assemble the required working components. Although this design idea reduces the coupling between various functions in the system, it also ignores the real correlation between various parts in the working assembly during the design of progressive die.

Therefore, according to the design points of progressive die for automobile structural parts, in view of the design difficulties of such die and the shortcomings of the existing progressive die design system, the rapid generation and relevance editing method of working components of progressive die are proposed, and a set of intelligent design and modification function module system for punching and trimming components of progressive die for automobile structural parts based on NX platform is developed. The system has been put into use in enterprises and achieved good results.

On the basis of analyzing the structural characteristics of progressive die for automotive structural parts, sorting out the typical blanking structures and design principles of standard hole blanking, special hole blanking, trimming, tongue cutting and other processes, and comprehensively applying the global parameter management idea, parametric and modular design, rule-based reasoning, dynamic assembly and other technologies, the functional module of progressive die punching and trimming is developed on the Siemens NX 8.5 software platform. The module is divided into three parts: global parameter management tool, component rapid generation tool and component editing tool, as shown in the figure. The user first initializes the shared parameters in the component design process according to the global parameter management tool, then uses the component rapid generation tool for structural variant design, and finally uses the component editing tool to adjust and edit the detailed features.