Manufacturing Process of Plastic Injection Molds Plastic

Injection Molds Plastic injection mold manufacturing involves a complex step-by-step process:

1、Material Procurement – Select suitable mold steel materials like P20, H13 based on longevity requirements.

2、Machining – Rough CNC machining to cut components as per CAD design. Precision CNC machining provides finishing.

3、Heat Treatment

Harden mold via processes like quenching and tempering to improve wear resistance and durability.

4、Surface Treatment

Treat mold core/cavity surfaces by chroming, polishing etc. to obtain desired finish on molded parts.

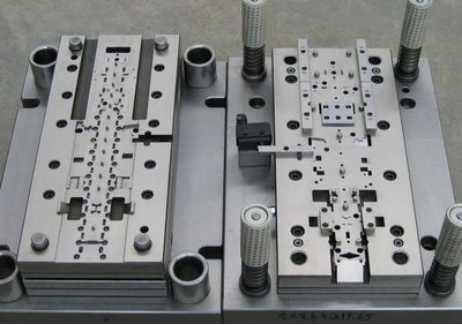

5、Mold Assembly

Assemble molded components and inserts. Check dimensional alignment of cavity and core halves.

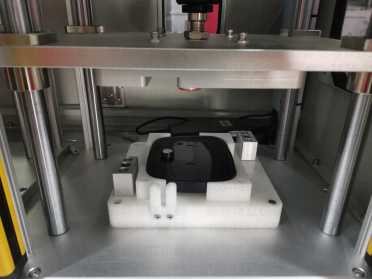

6、Mold Testing

Test mold using a plastic injection machine to ensure proper functioning. Refine mold as needed.

7、Documentation

Create documents for mold operation, maintenance and troubleshooting instructions.Strict process controls and quality checks during each step are vital for mold manufacturing.

Automation combined with expert craftsmanship results in high precision injection molds.