List the mistakes that are easy to make and the details that are easy to be ignored in the design of non-standard machinery

The non-standard design work involves a wide range of aspects. Because the nature of the profession is to solve problems in all aspects, non-standard designers are required to have a wide range of knowledge and knowledge. The more knowledge, the more effective the work, the more knowledge, the more experience, the more methods to solve problems, the faster and more accurate. Today, I would like to share with you the mistakes that are easy to make and the details that are ignored in non-standard mechanical design. I hope it will be helpful to you!

Major errors that must not occur in non-standard mechanical design

1. Design against laws and regulations

2. Matters not in conformity with the contract, or matters decided at the internal meeting with the customer and the company

3. No design basis (excluding experience design or feasible innovative design and invention design)

4. Failure to meet functional requirements and production capacity requirements

5. It cannot be disassembled

6. Big mistakes in model selection

7. Material selection error of important parts

8. There are big errors in the formulas and parameters in the calculation sheet

9. Errors in main dimensions, elevations, coordinates, etc

10. Serious interference

11. Excessive margin of equipment capacity

12. Potential safety hazard

13. Other major errors

Some common mistakes easily made in mechanical design

1. Nonconformity with drawing regulations

2. Insufficient calculation (calculation sheet)

3. Inadequate technical and operational requirements (notes on drawings)

4. Error in material list and parts list

5. Inconvenient maintenance

6. General collision

7. Error or insufficient tolerance, roughness, geometric accuracy, etc

8. General size error

9. View error

10. Errors in words or statements (more than 5 in total are considered as 1 general error)

12. Other general errors

Some Details Easily Neglected in Mechanical Design

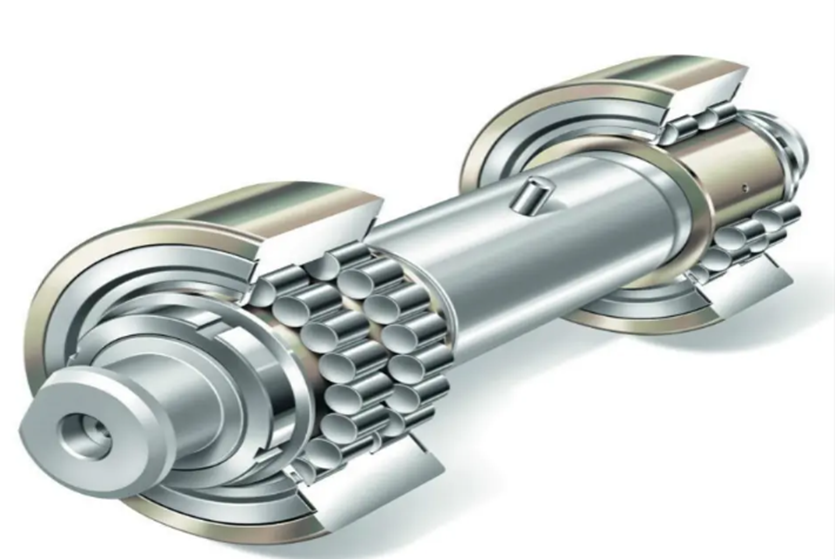

1. Designed lubricating point of rotating part (manual or automatic)

2. The rotating part is designed with a safety hood (with an observation door)

3. The design of lifting screw holes or lifting lugs for parts weighing more than 20kg

4. Adjusting bolts for design positioning and bearing of bearing pedestal mounting position

5. Design adjusting shim for connection surface involving height change or adjustment

6. Design locating pin or locating stop for bolted connection

7. Distinguish the site weldment from the factory welding

8. Special welding with non general welding requirements indicated

9. Sectional view of oil seal reflects oil seal direction

10. Double nut loosening for large piece connection design

11. Indicate the scope of non painting

12. Motion range (start and end positions) and motion track representation of moving parts

13. Safety design in working state and non working state

14. Strengthen load-bearing parts (such as stiffeners) and weaken non load-bearing parts (such as weight reduction holes)

15. Improve design linear tolerance, fit tolerance and geometric tolerance

16. Reasonably design the processing roughness

17. Accurate preparation of technical requirements