Laser cutting, laser welding technology and its typical applications

Since the first ruby laser was developed by American scientist Meiman in 1960, with the needs of the world’s scientific and economic development, the laser technology has developed rapidly, especially in recent decades, which has greatly promoted the wider application of laser processing technology. Compared with ordinary light, laser has four characteristics, namely monochromaticity (single wavelength), coherence, directivity and high light intensity.

The laser beam is easy to transmit, and its temporal and spatial characteristics can be controlled respectively. After focusing, a very small spot can be obtained. The laser beam with very high power density can melt and gasify any material, and can also carry out precision and rapid machining in local areas. In the machining process, the input heat of the workpiece is small, the heat affected zone and thermal deformation are small; High processing efficiency and easy to realize automation. Laser technology is a comprehensive high-tech, involving optics, mechanics, electronics and other disciplines. Similarly, laser processing equipment also involves many disciplines, which determines its high-tech and high yield. Looking at the international and domestic laser application fields, after years of research, development and improvement, Contemporary laser and laser processing technology and equipment have been quite mature, forming a series of laser processing technology. In addition, various new laser processing technologies are still emerging.

In terms of the actual application proportion in the international scope, laser processing is mainly used for cutting, welding, surface treatment, marking and drilling. Two dimensional and three-dimensional laser cutting accounts for 65% of laser applications, laser welding accounts for about 20%, laser drilling and marking account for less than 10%, while laser surface treatment, including laser phase transformation hardening, laser cladding, laser surface alloying and laser surface melting, accounts for only about 5%. From the development and application of domestic laser processing technology, more and more users have realized the unique excellent performance, high flexibility and high efficiency of laser processing. At present, laser technology has long been popularized in aerospace, automobile manufacturing, switch industry, gear industry, railway locomotive manufacturing and metal material processing industry.

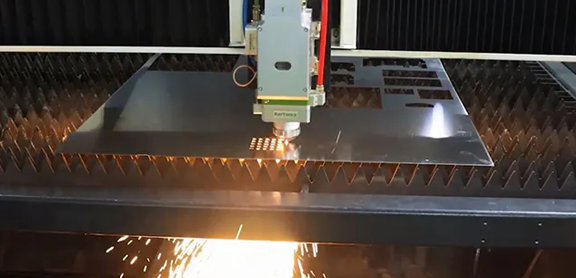

1、 Characteristics and application of laser cutting

Laser cutting is the most widely used laser processing technology in various countries, and it is widely used in many fields abroad For example, both automobile manufacturing and machine tool manufacturing use laser cutting to process sheet metal parts. With the improvement of beam quality of high-power laser, the range of processing objects of laser cutting is wide It includes almost all metal and non-metallic materials. For example R, laser can be used to cut complex three-dimensional parts of materials with high hardness, high brittleness and high melting point, which is the advantage of laser cutting.

2、 Main advantages of laser cutting

1. Laser cutting is non-contact optical thermal processing, which is known as the “universal tool that will never wear”. The workpiece can be closely arranged or nested in any form to make full use of raw materials. Due to non-contact processing, the processed parts have no deformation.

2. High efficiency of laser cutting. Taking 1 mm thick aluminum alloy plate as an example, the cutting speed can reach 40 m / min. High efficiency makes the cost of single piece machining reduced geometrically or even lower than that of traditional machining methods.

3. Laser cutting does not require tools and molds. Under the control of computer, the flexible machining of plate and shell parts with arbitrary shape in two and three dimensions can be realized directly It is especially suitable for the processing of multi variety and small batch rice metal parts in the research and development stage of new products, which can save the high cost of mold design and manufacturing, and greatly shorten the production cycle.

4. The cutting seam of laser cutting is very small, and the cutting seam is generally between 0.15-0.4 mm. The notch is smooth and burr free, and can even directly process the finished product of transmission spur gear with certain accuracy.

3、 Characteristics and application of laser welding

Laser welding is a welding method with high speed, non-contact and minimal deformation, which is very suitable for large and continuous on-line processing. With the development of laser equipment and processing technology, the ability of laser welding is also increasing. At present, 4kw laser is used to weld 1mm plates, and the welding speed is up to 20 m / min, such as the splicing and welding of large plates at the bottom of car boxes in the automotive industry. There are two main ways of laser welding: conduction welding and penetration welding. At present, penetration welding is the main laser application in the world. Laser welding is one of the important aspects of the application of lf2700ha technology in laser material processing.

4、 Advantages of laser welding

Wuhan farilai company was the first to win the title of “national Laser Laboratory”. Compared with other welding technologies, its laser welding machine has the following main advantages:

1. The laser welding speed is fast, the weld depth width ratio is very large (up to 5-10), and the deformation is small.

2. It is very suitable for processing precision parts, box parts and weldments with sealing requirements. After the laser beam is gathered, a small spot can be obtained and can be accurately positioned It can be applied to mass automatic production Not only the production efficiency is greatly improved, but also the heat affected zone is small and the welding joint is pollution-free, which greatly improves the welding quality.

3. The mechanical properties of laser weld are good, and the mechanical properties of general weld are stronger than that of base metal.

4. There is no need for shielding or vacuum environment during welding, which is of great significance to industrial scale production.

5. Through new technologies such as laser wire feeding welding and laser powder feeding welding, the industrialized application of laser is realized, and the application field of laser welding is developed

6. The inaccessible parts can be welded and non-contact long-distance welding can be implemented. Especially in recent years, optical fiber transmission technology has been adopted in YAG laser processing technology, which makes laser welding technology more widely popularized and applied.

In short, laser welding has the following advantages: high strength and long service life: high welding speed and efficiency, simple lap joint process, low scrap rate and low positioning accuracy. It is suitable for industrialized production. It is mainly used in military enterprises, food industry, chemical industry and petrochemical industry.

5、 Typical application

1. Application of laser welding technology in heat exchanger

Laser welding has been widely used in heat exchanger industry because of its high reliability and high efficiency. There are many problems in the products R of heat exchanger industry, such as multiple welds, complex structure and bad working environment, which restrict the development of products. The successful application of laser welding technology in this industry not only improves the competitiveness of products, but also greatly reduces the manufacturing cost and production cycle. Foreign related products have been widely used on a large scale.

2. Application of laser welding in switch industry

High voltage SF6 switchgear is the leading product in the high voltage switchgear industry. This product requires reliable sealing in the natural environment for more than 30 years. For such large box parts, traditional welding methods not only face the problems of deformation and poor air tightness after processing, but also face the low processing efficiency High cost and many other problems. The modular design of three-dimensional laser processing machine tool can realize the laser welding task of switch box with curved surface

Special welding power control options, weld tracking system, programmable protective gas system and laser wire feeding welding device make the welding quality fully meet the requirements of mass industrialization. The adoption of three-dimensional programming software not only greatly improves the efficiency, but also reduces the scrap rate to the lowest. Now the world’s famous high-voltage switch manufacturers use tongkuai’s three-dimensional laser processing equipment for cutting and welding of corresponding parts. For example, AUMA Garbo, abb and Siemens in Europe all use tongkuai’s three-dimensional equipment for high-voltage SF6. Cutting and welding of electrical cabinet box. In the near future, users in the switching industry will also carry out such applications in China.

3. Application of laser welding in gear machining

The process of laser welding gear fundamentally changes the traditional design and manufacturing concept, and provides a better economic ratio and more compact structure for the processing of gear box components. Using the laser welding gear process, the whole annular long gear ring needs to be processed first, and then cut into several gear rings Then weld on the transmission shaft according to the requirements of the gearbox.

Laser processing technology has been widely used in many fields. With the deepening of the research on laser processing technology, equipment and technology, it will have a broader application prospect.