In-depth Analysis of Plastic Injection Mold Design

The design of a high quality plastic injection mold requires expertise and careful planning. Key design factors include:

1、Product design analysis

Analyze part design、size、geometry、 weight、 function、material etc. This helps optimize mold design.

2、Mold type selection

Choose suitable mold type (e.g. two-plate, three-plate, hot runner). It impacts mold cost and injection process.

3、Material selection

Select plastic material based on product specifications. Popular materials include PP、ABS、 POM、 PC etc.

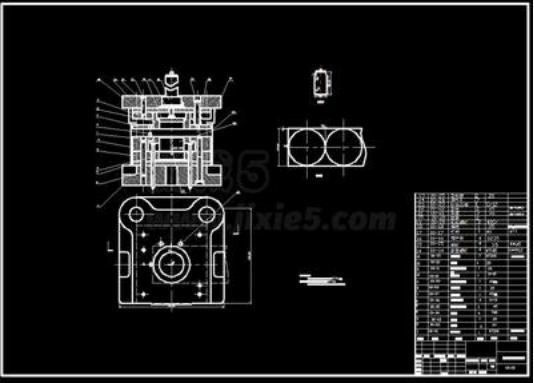

4、Mold CAD software design

Use specialized CAD software for mold design. It facilitates modeling of mold components like cavity、core、sliders、 ejectors etc.

5、Cooling system design

Design efficient cooling channels to dissipate heat and solidify plastic faster. Uniform cooling prevents defects.

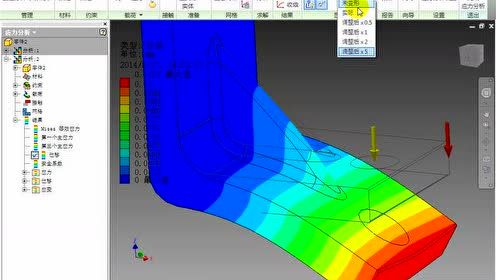

6、Simulation analysis

Perform mold filling and cooling simulations using CAE software like Mold flow. This validates design before machining.

Proper mold design is critical for good part quality, longer tool life and optimized production. A scientific design approach and advanced software ensure an efficient precision mold.