How to select welding materials for stainless steel

The role of four types of stainless steel and alloy elements

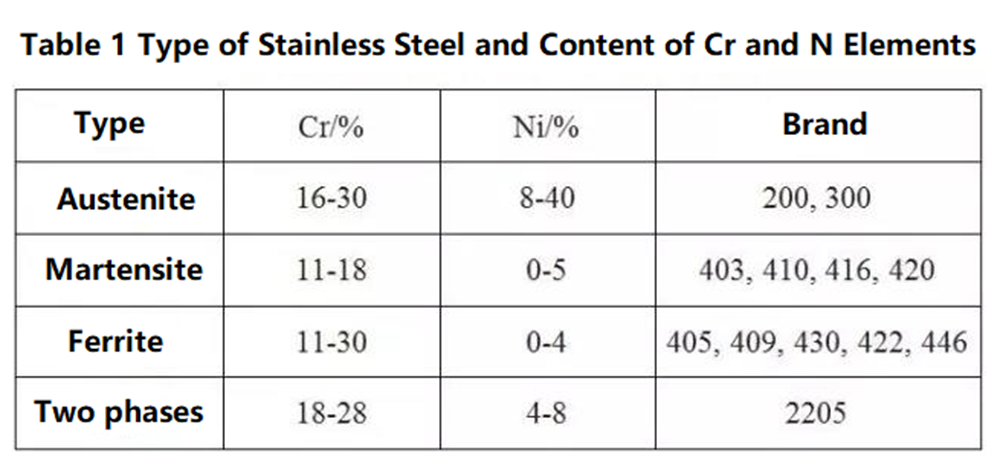

Stainless steels can be divided into four types: austenitic, martensitic, ferritic and duplex stainless steels (Table 1).

This is based on the metallographic structure of stainless steel at room temperature. When low carbon steel is heated to 1550 ℉, its structure changes from ferrite phase at room temperature to austenite phase. When cooling, the microstructure of low carbon steel is transformed into ferrite again. The austenite structure at high temperature is nonmagnetic, and its strength is smaller and toughness is better than that of room temperature ferrite.

When the Cr content in the steel is more than 16%, the ferrite structure at room temperature is fixed so that the steel can maintain the ferrite state in all temperature ranges. Therefore, it is called ferritic stainless steel. When Cr content is greater than 17% and Ni content is greater than 7%, the austenite phase is fixed, so that the austenite state is maintained from low temperature to almost melting point.

Austenitic stainless steels are usually called “Cr Ni” type, while martensitic and ferritic stainless steels are directly called “Cr” type. The elements in stainless steel and filler metal can be divided into austenite forming elements and ferrite forming elements. The main austenite forming elements are Ni, C, Mn and N, and the ferrite forming elements are Cr, Si, Mo and Nb. The ferrite content in the weld can be controlled by adjusting the element content.

Austenitic stainless steel is easier to weld and has better welding quality than stainless steel with Ni content less than 5%. Austenitic stainless steel welded joints have good strength and toughness, and generally do not need preheating before welding and post welding heat treatment. In the field of stainless steel welding, austenitic stainless steel accounts for 80% of the total stainless steel consumption, so this paper focuses on the welding of austenitic stainless steel.

How to select the correct stainless steel welding materials?

If the base metal is the same, the first rule is “match with the base metal”. For example, when welding 310 or 316 stainless steel, select the corresponding welding materials.

For welding dissimilar materials, the criterion of matching the base metal with high alloy element content shall be followed. For example, for welding 304 and 316 stainless steel, select 316 welding material.

However, there are also many special cases that do not follow the principle of “matching base metal”, so it is necessary to “consult the welding material selection table”. For example, 304 stainless steel is the most common base metal, but there is no 304 welding rod.

If you want to match the welding materials with the base metal, how do you choose welding materials to weld 304 stainless steel?

When welding 304 stainless steel, use 308 welding material, because the additional elements in 308 stainless steel can better stabilize the weld area.