Hand board surface treatment process ③: Wire Drawing

The term “wire drawing” may be unfamiliar to many laymen, but I believe most people have seen common products made by wire drawing. For example, aluminum thermos bottles, aluminum bowls and aluminum windows have been treated with wire drawing technology. So, what is wire drawing and how is it made?

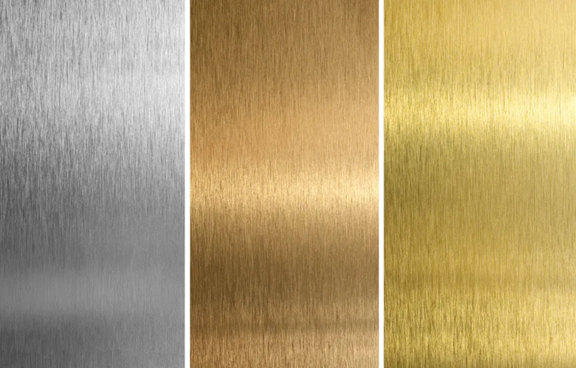

Wire drawing is a kind of metal processing technology. In metal pressure machining, the metal is forced through the die under the action of external force, the metal cross-sectional area is compressed, and the required cross-sectional area shape and size are obtained. The technical processing method is called metal wire drawing process. Hand board surface wire drawing treatment is a surface treatment method to form lines on the surface of workpieces by grinding products and play a decorative effect. Because the wire drawing treatment on the surface of the hand board can reflect the texture of metal materials, it has been loved by more and more users and widely used. Hand drawing can be made into straight lines, random lines, threads, ripples and spiral lines according to the decoration needs of customers.

At present, the common mature wire drawing methods include flat pressing abrasive belt wire drawing, non-woven roller wire drawing, wide abrasive belt wire drawing and centerless grinding wire drawing. The wire drawing process of the hand board can choose different wire drawing according to the appearance of the workpiece or the type loved by customers.