Experience in 12 machining

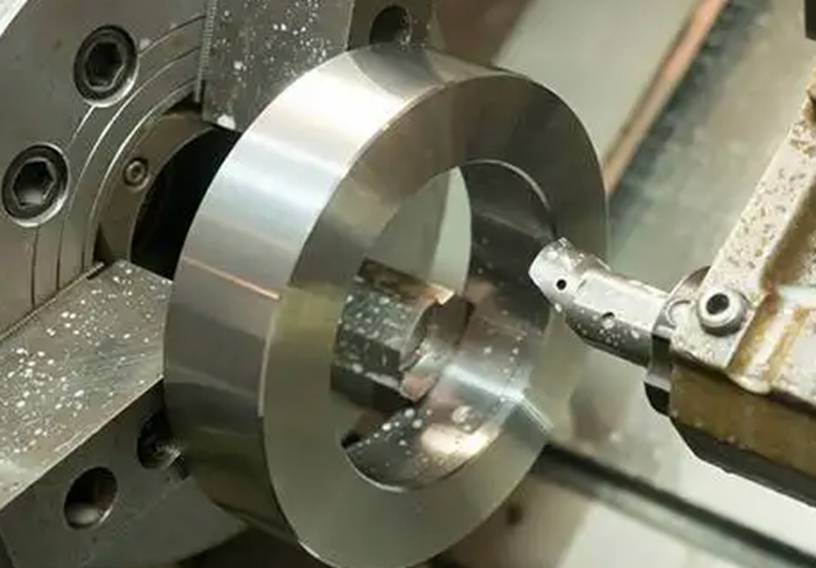

Due to the complexity of NC processing (such as different machine tools, different materials, different tools, different cutting methods, different parameter settings, etc.), it must take a long time from engaging in NC processing (whether processing or programming) to reaching a certain level. This manual is summarized by engineers in the long-term actual production process A summary of experience in the selection of commonly used tool parameters and monitoring in the process of machining is available for your reference.

1、 Q: How to divide processing operations?

Answer: NC processing procedures can be divided according to the following methods:

(1) The centralized tool sorting method is to divide the working procedure according to the tool used, and use the same tool to process all the parts that can be completed on the part. Use the second knife and the third knife to complete other parts that they can complete. This can reduce the number of tool changes, compress the idle time and reduce unnecessary positioning errors.

(2) For parts with a lot of processing content, the processing part can be divided into several parts according to its structural characteristics, such as internal shape, shape, curved surface or plane. Generally, the plane and positioning surface are processed first, and then the hole is processed; First process simple geometric shapes, then process complex geometric shapes; The parts with lower accuracy shall be processed first, and then the parts with higher accuracy requirements shall be processed.

(3) For the parts that are easy to be deformed by rough and finish machining in sequence, due to the deformation that may occur after rough machining, it is necessary to calibrate, so generally speaking, all processes that need to be rough and finish machined should be separated.

To sum up, when dividing processes, it is necessary to flexibly master the structure and processability of parts, the function of machine tools, the number of NC machining contents of parts, the number of installation times and the production organization of the unit. In addition, it is suggested to adopt the principle of process centralization or process decentralization, which should be determined according to the actual situation, but must be reasonable.

2、 Q: What principles should be followed in arranging the processing sequence?

Answer: The processing sequence should be arranged according to the structure of the part and the blank condition, as well as the need for positioning and clamping. The key is that the rigidity of the workpiece will not be damaged. The sequence shall generally follow the following principles:

(1) The processing of the previous process shall not affect the positioning and clamping of the next process, and the processing of general machine tools interspersed between them shall also be considered comprehensively.

(2) The internal cavity processing sequence is carried out first, and then the contour processing sequence is carried out.

(3) It is better to connect the processes of the same positioning, clamping method or the same knife processing to reduce the times of repeated positioning, tool change and moving the pressing plate.

(4) For multiple processes in the same installation, the process with small rigid damage to the workpiece shall be arranged first.

3、 Question: What aspects should be paid attention to when determining the clamping mode of the workpiece?

Answer: Pay attention to the following three points when determining the positioning datum and clamping scheme:

(1) Strive to unify the design, process and programming calculation.

(2) The clamping times shall be reduced as far as possible, and all surfaces to be machined can be machined after one positioning.

(3) Avoid using manual adjustment scheme for machine occupation.

(4) The fixture shall be open smoothly, and its positioning and clamping mechanism shall not affect the tool path during processing (such as collision). In such cases, it can be clamped with a vise or by adding a base plate to draw screws.

4、 Q: How to determine a reasonable tool setting point? What is the relationship between the workpiece coordinate system and the programming coordinate system?

1. The tool setting point can be set on the part to be machined, but it should be noted that the tool setting point must be the reference position or the part that has been finished. Sometimes the tool setting point is destroyed after the first process, which will lead to no way to find the tool setting point in the second process and the subsequent process. Therefore, when aligning the tool in the first process, it should be noted that a relative tool setting position should be set where there is a relatively fixed dimension relationship with the positioning reference, In this way, the original tool setting point can be found according to the relative position relationship between them. This relative tool setting position is usually set on the machine tool workbench or fixture. The selection principles are as follows:

1) It’s easy to find it.

2) Easy programming.

3) The tool setting error is small.

4) It is convenient to check during processing.

2. The origin position of the workpiece coordinate system is set by the operator. After the workpiece is clamped, it is determined by tool setting. It reflects the distance position relationship between the workpiece and the zero point of the machine tool. Once the workpiece coordinate system is fixed, it is generally unchanged. The workpiece coordinate system and the programming coordinate system must be unified, that is, during processing, the workpiece coordinate system and the programming coordinate system are consistent.

5、 Q: How to choose the cutting route?

Tool path refers to the path and direction of the tool relative to the workpiece in the process of NC machining. The reasonable choice of machining route is very important, because it is closely related to the machining accuracy and surface quality of parts. The following points are mainly considered when determining the tool path:

1) Ensure the machining accuracy requirements of parts.

2) It is convenient for numerical calculation and reduces programming workload.

3) Find the shortest processing route, reduce the empty tool time to improve the processing efficiency.

4) Minimize the number of program segments.

5) Ensure the roughness requirements of the workpiece contour surface after machining. The final contour shall be processed continuously with the last cutter.

6) The advance and retreat (cut in and cut out) route of the tool shall also be carefully considered to minimize the tool marks caused by tool stopping at the contour (elastic deformation caused by sudden change of cutting force), and also to avoid scratching the workpiece due to vertical cutting on the contour surface.

6、 Q: How to monitor and adjust during processing?

The workpiece can enter the automatic processing stage after the alignment and program debugging are completed. In the automatic machining process, the operator shall monitor the cutting process to prevent the workpiece quality problems and other accidents caused by abnormal cutting.

The monitoring of cutting process mainly considers the following aspects:

1. The monitoring of the machining process mainly considers the rapid removal of the surplus allowance on the workpiece surface. In the automatic machining process of the machine tool, the tool automatically cuts according to the predetermined cutting path according to the set cutting parameters. At this time, the operator should observe the change of cutting load during automatic processing through the cutting load table, and adjust the cutting parameters according to the bearing force of the tool to maximize the efficiency of the machine tool.

2. Monitoring of cutting sound in the cutting process In the automatic cutting process, the sound of the tool cutting workpiece is stable, continuous, and light when cutting is generally started, and the movement of the machine tool is stable. With the progress of the cutting process, when there are hard spots on the workpiece or the tool is worn or the tool is clamped, the cutting process becomes unstable. The unstable performance is that the cutting sound changes, the tool and the workpiece will collide with each other, and the machine tool will vibrate. At this time, the cutting parameters and cutting conditions should be adjusted in time. When the adjustment effect is not obvious, the machine tool should be paused to check the condition of the tool and workpiece.

3. The finishing process is monitored to ensure the machining size and surface quality of the workpiece. The cutting speed is high and the feed rate is large. At this time, attention should be paid to the influence of chip buildup on the machined surface. For cavity machining, attention should also be paid to over cutting and tool passing at corners. To solve the above problems, first, pay attention to adjusting the spraying position of cutting fluid, so that the machined surface is always in the best cooling condition; Second, pay attention to the quality of the machined surface of the workpiece, and try to avoid quality changes by adjusting the cutting parameters. If the adjustment still has no obvious effect, stop the machine to check whether the original program is reasonable.

In particular, pay attention to the position of the tool when suspending inspection or stopping inspection. If the tool stops in the cutting process and the spindle stops suddenly, tool marks will be generated on the workpiece surface. In general, shutdown shall be considered when the tool leaves the cutting state.

(4) The quality of the tool monitoring tool largely determines the processing quality of the workpiece. In the process of automatic machining and cutting, it is necessary to judge the normal wear condition and abnormal damage condition of tools by means of sound monitoring, cutting time control, pause inspection during cutting, workpiece surface analysis, etc. Tools shall be handled in time according to the processing requirements to prevent the processing quality problems caused by the tools not being handled in time.

7、 Q: How to reasonably select the machining tool? How many elements are there in the cutting parameters? How many materials are there? How to determine the tool speed, cutting speed, cutting width?

1. The carbide end milling cutter or end milling cutter without regrinding shall be selected for plane milling. In general milling, try to use the second tool path for processing. The first tool path is better to use the end milling cutter for rough milling, and the tool path is continuous along the workpiece surface. The recommended width of each tool path is 60% – 75% of the tool diameter.

2. End milling cutter and end milling cutter with carbide insert are mainly used to process boss, groove and box mouth surface.

3. Ball knife and round knife (also known as round nose knife) are commonly used to process curved surfaces and variable angle contour shapes. The ball cutter is mostly used for semi finishing and finishing. The round cutters with carbide inserts are mostly used for roughening.

8、 Q: What is the function of the processing program sheet? What should be included in the processing program sheet?

Answer: (I) The processing program list is one of the contents of the NC processing process design, is also a procedure that needs to be observed and implemented by the operator, and is a specific description of the processing program. The purpose is to let the operator know the content of the program, the clamping and positioning methods, and the problems that should be paid attention to when selecting the tools for each processing program.

(2) In the processing program list, it shall include: drawing and programming file name, workpiece name, clamping sketch, program name, tool used in each program, maximum depth of cutting, processing nature (such as rough machining or finish machining), theoretical processing time, etc.

9、 Q: How to prepare for NC programming?

Answer: After determining the processing technology, we should understand the following before programming: 1. Workpiece clamping method; 2. Size of work-piece rough – to determine the processing range or whether multiple clamping is required; 3. The material of the workpiece – in order to choose which tool to use for processing; 4. What are the tools in stock? Avoid modifying the program when there is no such tool. If you must use this tool, you can prepare in advance.

10、 Q: What are the principles for setting the safe height in programming?

Answer: The setting principle of safe height is generally higher than the highest surface of the island. Or set the programming zero point at the highest plane, so as to avoid the danger of knife collision to the greatest extent.

11、 Q: Why should post processing be performed after the tool path is compiled?

Answer: Because the address code recognized by different machine tools is different from the NC program format, the correct post-processing format must be selected for the machine tool used to ensure that the compiled program can run.

12、 Q: What is DNC communication?

Answer: There are two ways of program transmission: CNC and DNC. CNC refers to that the program is stored in the memory of the machine tool through the media (such as floppy disk, tape reader, communication line, etc.), and the program is called out from the memory for processing. Because the memory capacity is limited by the size, when the program is large, the DNC method can be used for processing. Because the machine tool reads the program directly from the control computer (that is, it is not limited by the size of the memory capacity) during DNC processing.

(2) There are three elements of cutting parameters: cutting depth, spindle speed and feed speed. The general principle for the selection of cutting parameters is: less cutting and fast feed (i.e., small cutting depth and fast feed speed).

(3) According to the classification of materials, tools are generally divided into ordinary hard white steel tools (made of high-speed steel), coated tools (such as titanium plating) and alloy tools (such as tungsten steel and boron nitride tools).