Don’t hit it with a hammer. This is the correct way to disassemble the bearing

The disassembly of rolling bearing is one of the important disassembly contents in mechanical maintenance. Disassembly must follow the basic rules of bearing disassembly and assembly, and different disassembly tools and methods should be adopted for different bearings. When the bearing fits tightly with the shaft and loosely with the seat hole, the bearing and the shaft can be removed from the housing together, and then the bearing can be removed from the shaft with a press or other removal tools.

Here are some common bearing disassembly methods:

1. Removal of inner / outer ring.

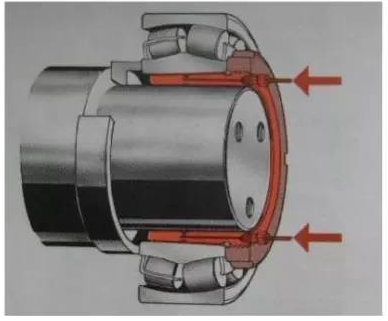

Remove the outer ring of the interference fit. Set several screws for the outer ring extrusion screw on the circumference of the shell in advance. Tighten the screw equally while removing. These screw holes are usually covered with blind plugs, tapered roller bearings and other separate bearings. Several cuts are set on the housing shoulder. Use cushion blocks, disassemble with a press, or knock gently.

2. Disassembly of cylindrical bore bearing

It is easiest to pull out with a press. At this time, pay attention to make the inner ring bear its pulling force. The inner ring of large bearing is disassembled by oil pressure method. Oil pressure is applied through the oil hole arranged on the shaft to make it easy to pull out. The bearing with large width can be disassembled only when the oil pressure method is combined with the drawing fixture. The inner ring of Nu and NJ cylindrical roller bearings can be disassembled by induction heating method. It is a method of heating part in a short time to expand the inner ring and then drawing.

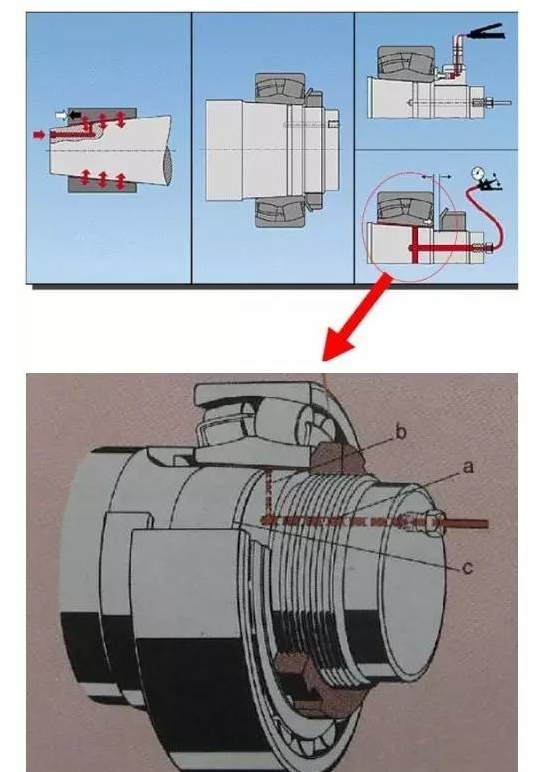

3. Disassembly of tapered bore bearing

Disassemble the relatively small bearing with fixed sleeve, support the inner ring with the stop fastened on the shaft, turn the nut back several times, use the cushion block and knock it with a hammer for disassembly. For large bearings, it is easier to disassemble by oil pressure. Pressurize the oil in the oil hole on the taper hole shaft to expand the inner ring and disassemble the bearing. During operation, there is a risk of sudden bearing detachment. It is best to use the nut as a stop.

4. Knock off method

Knock off is one of the simplest and most common disassembly methods. It is a disassembly method that uses the force of hammering to make the matched parts displace and separate from each other, so as to achieve the purpose of disassembly. The structure of the parts is relatively simple, the parts are solid or some unimportant parts are mostly disassembled by this method. Before disassembly, in order to reduce friction, the joint is often soaked with lubricating oil. Knock down is a simple and easy disassembly method. The commonly used tools for striking and dismantling are hand hammer, i.e. ordinary fitter’s hand hammer, punch and cushion block. The punch is made of steel, and the hammered top is processed into a sphere, so that the end in contact with the workpiece is usually inlaid with soft metal, such as copper, aluminum, etc., and made into a flat or suitable shape for the workpiece, so as to protect the surface of the workpiece from damage. Different methods and steps shall be taken according to different parts structure during unloading. Sliding bearing bushing and rolling bearing sleeve belong to interference fit in the hole. They are also commonly removed from the hole. When the bushing is hammered, the end face of the bushing should be padded with cushion blocks. When removing the bushing with small diameter, it is best to use a step punch. The small diameter of the punch is just matched with the inner hole of the bushing. The large diameter of the punch is about 0.5mm smaller than the outer diameter of the bushing. For the disassembly of large-diameter bushing and rolling bearing, casing is often used. For the disassembly of ordinary small bearing cover, the method of symmetrically driving the inclined pad is often used to open the bearing cover.

5. Pressure relief and pull relief

Pressure unloading and pull unloading have many advantages over impact unloading. It applies force evenly, and the size and direction of force are easy to control. It can disassemble large parts and parts with large interference, and this disassembly method has less chance of damaging parts. Pressure relief and corresponding tools are required. Pressure relief requires the use of pressure machine tools. The commonly used pressure machine tools include mechanical press, friction press and hydraulic press. The drawing die is often used for pulling and unloading. The drawing die is divided into fixed arm and movable arm, as well as two claws and three claws. The tensile force added by the claws of the drawing die should be added to the inner ring of the bearing. When the structure is special and the inner ring cannot be pulled, the outer ring can be pulled.