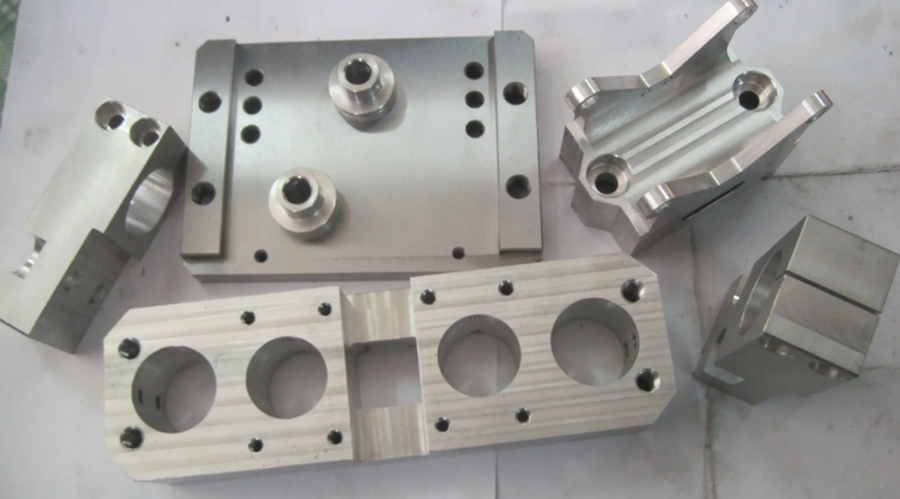

Disassembly of mechanical equipment parts

The parts and components of mechanical equipment are closely related to the work and use. Therefore, when using mechanical equipment, we need to maintain not only the equipment, but also the parts and components. Otherwise, it will affect the normal work of mechanical equipment and reduce its use performance. Based on our understanding, China Standard Parts Network told you about the disassembly of mechanical equipment parts and components, hoping to help you use them.

1. The disassembly shall be carried out in order, and the general principle is the reverse order of assembly. Generally, they are removed from the outside to the inside, from the top to the bottom, and then in turn. If there is no installation drawing, an installation sketch shall be drawn first to avoid installation after removal.

2. According to the type of assembly parts, the parts shall be decontaminated, derusted, cleaned and properly kept to avoid overlapping, bending, scratching and contamination. The smaller parts shall be packed for storage. Some parts such as shaft, gear, screw, J nut, key, gasket, locating pin, etc. shall be sleeved together according to the original structure as far as possible to avoid confusion.

3. In order to facilitate rapid assembly after maintenance, relevant mating parts and components can be printed and marked during disassembly.

4. Do a good job of checking, lining and calibrating the availability, repair and scrapping of parts. During calibration, it shall be noted that the causes of wear and damage of parts and the service life of parts shall be registered as historical data. Three types of parts are distinguished as follows.

1) Usable parts: After inspection, the wear degree is within the allowable range, and there is no damage. They can still be used without repair.

2) Parts to be repaired: after inspection, the wear degree has exceeded the allowable range, or there is local damage and damage, but they can continue to be used after repair.

3) Scrapped parts: after inspection, they may be repaired, or they will not be repaired due to high repair costs.

5) When disassembling parts and components that are complex or difficult to disassemble, it is necessary to know the structure of the parts, the connection mode with other parts and the loosening direction of the parts in advance, and prepare special or corresponding tools and fixtures.

6. When it is necessary to use a hammer to knock parts for disassembly, a wooden pad or soft metal (such as copper lead) must be padded. Never directly hammer parts. The hammering point should be appropriate (preferably at the center of gravity of the part), and the hammering force should not be too large (except in special cases). It must be noted that some parts are not allowed to be hammered, and in this case, it is better to use a press to disassemble them.

7. In case of destructive removal, another part connected with it must not be damaged, such as bending, bursting, deformation, lifting and gas cutting wounds.

8. When disassembling parts and components and lifting large parts and components, safety measures shall be taken to prevent personal or color steel tile mechanical equipment accidents.