Common Problems and Countermeasures of TPU Injection Molding Products

Causes and Solutions of Injection Molding Defects of TPU Products

During the injection molding of thermoplastic polyurethane (TPU), the dried and preheated TPU granules are transported from the hopper of the injection molding machine to the heated barrel. When they are in the molten state, they are injected into the closed mold with relatively low temperature through the propelling action of the screw (or plunger) and the nozzle at the front end of the barrel to fill the mold cavity, and are cooled and solidified under pressure. After demoulding, the same TPU product as the mold cavity is obtained. [ 1〕

From the TPU injection molding process, the most important molding conditions of TPU injection molding products are the temperature, pressure and time that affect the plasticizing flow and cooling. [ 2] In view of the characteristics of TPU, especially its narrow processing temperature fluctuation range, the injection molding machine must be equipped with an accurate temperature regulation and control system, otherwise it will cause product defects due to various factors. If we include the causes of secondary waste products in the four main factors, that is, raw materials, molds, injection molding machines and injection conditions.

In principle, TPU molded products are manufactured according to standard specifications. However, its changes are still quite extensive and sudden. Sometimes, secondary waste products such as depression, bubble, crack and deformation will be produced in the production process. Therefore, it is necessary to understand and judge the problem from the secondary waste products and propose solutions, which is the accumulation of professional technology and practical experience. In fact, sometimes it is only necessary to change the operating conditions or slightly deal with and adjust the raw materials, molds and machines to solve the problem. Taking the TPU product produced by screw injection molding machine as an example, this paper lists the possible problems and causes of TPU injection molding product defects, and discusses the solutions.

1、 The product is sunken

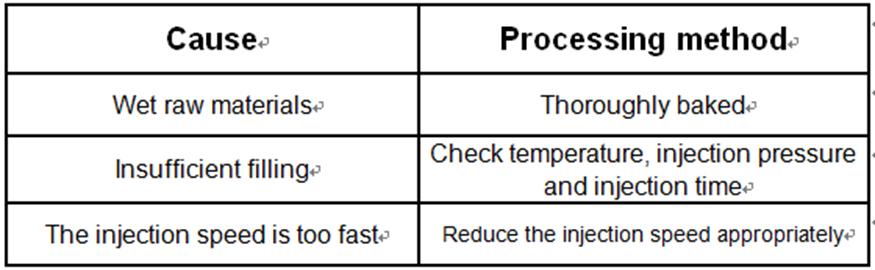

The depression on the surface of TPU products will reduce the quality and strength of finished products, and also affect the appearance of products. The cause of the depression is related to the raw materials used, molding technology and mold design, such as the shrinkage of raw materials, injection pressure, mold design and cooling device.

Table 1 shows the possible causes and treatment methods of depression.

2、 The product has bubbles

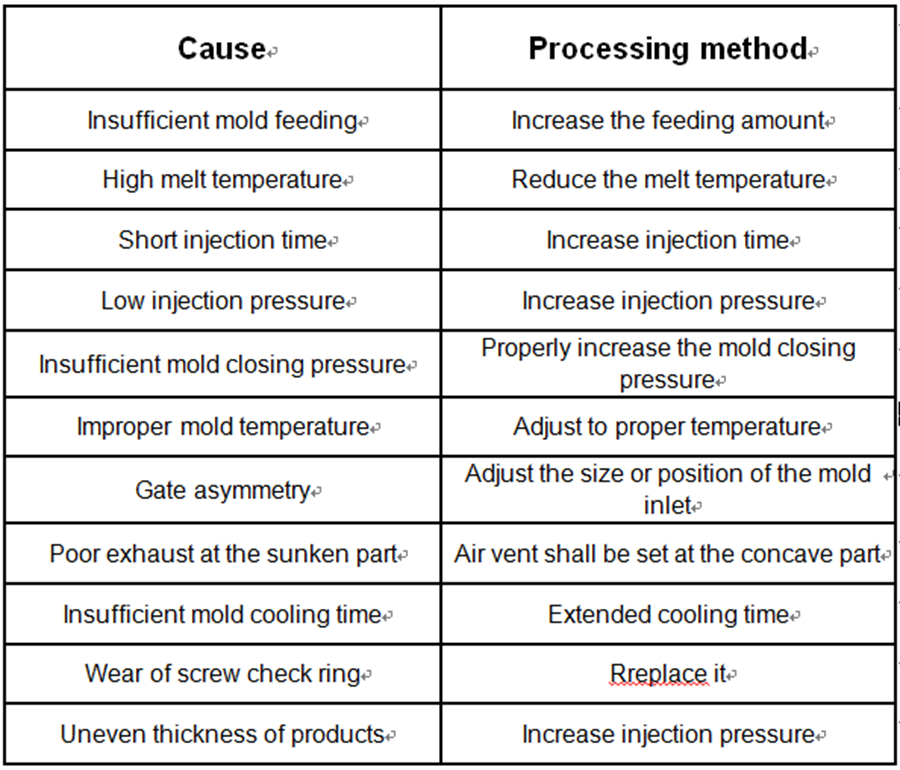

In the injection molding process, the products sometimes have many bubbles, which will affect their strength and mechanical properties, and greatly discount the appearance of the products. Generally, due to uneven thickness of products, or when the mold has protruding ribs, the cooling speed of materials in the mold is different, resulting in uneven shrinkage, which is easy to form bubbles. Therefore, special attention should be paid to mold design.

In addition, the raw materials are not dry enough, and still contain some water, which will be decomposed into gas when heated during melting, and easy to enter the mold cavity to form bubbles. Therefore, when bubbles appear in products, the following factors can be checked and handled.

Table 2: Possible causes and treatment methods of bubbles.