Common cutting process

Common cutting processes include water cutting, EDM, gas fuel cutting, plasma cutting, die cutting, sawing, wire cutting, laser cutting, etc. Comparison of common cutting processes:

Cutting process | Slot deformation precision Graph change speed usage

Laser cutting | Very small, very high, very easy, high, low

Gas fuel cutting | very serious low easy low

Plasma cutting | larger, larger, lower, easier, higher, lower

Die stamping | small, large, low and difficult (large quantity)

Sawing | Large, small, low, difficult, slow, low

Wire cutting | small, small, high, easy, slow, high

Water cutting | Large high easy high high

EDM | Very small, very high, very easy, very slow, very high

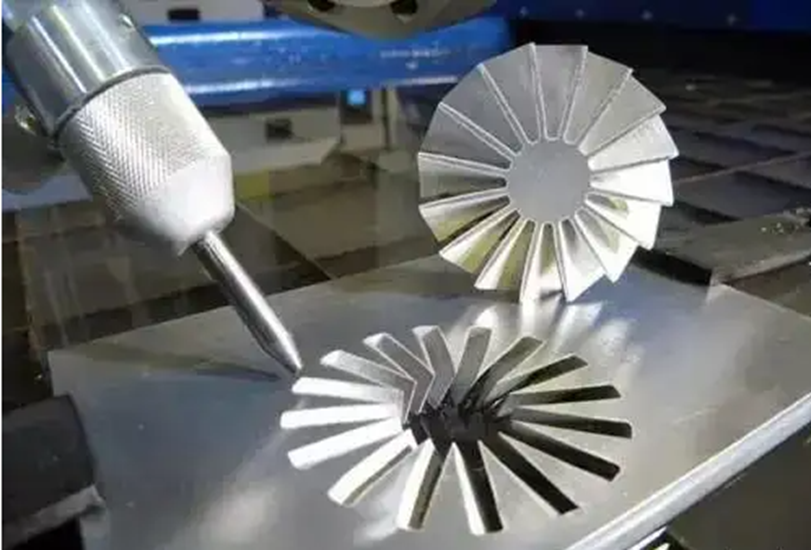

Laser cutting process can be divided into:

1. Vaporization cutting

Under the heating of high power density laser beam, the speed at which the material surface temperature rises to the boiling point temperature is fast enough to avoid melting caused by heat conduction, so some materials vaporize into steam and disappear, and some materials are blown away from the bottom of the slit by the auxiliary gas flow as ejectors.

2. Melting and cutting

When the power density of the incoming laser beam exceeds a certain value, the material inside the beam irradiation point evaporates, forming holes. Once this hole is formed, it will act as a blackbody to absorb all the incoming beam energy. The hole is surrounded by a wall of molten metal, and then the auxiliary air flow coaxial with the beam carries away the molten material around the hole. As the workpiece moves, the small hole moves horizontally in the cutting direction synchronously to form a slit. The laser beam continues to irradiate along the front edge of the seam, and the molten material is continuously or pulsantly blown away from the seam.

3. Oxidation, melting and cutting

Inert gas is generally used for melting and cutting. If oxygen or other active gases are used instead, the material will be ignited under the irradiation of laser beam, which will produce another heat source through violent chemical reaction with oxygen, which is called oxidation melting and cutting.

4. Control fracture cutting

For brittle materials that are easy to be damaged by heat, high-speed and controllable cutting is conducted by laser beam heating, which is called controlled fracture cutting. The main content of this cutting process is that the laser beam heats a small area of brittle material, causing large thermal gradient and serious mechanical deformation in the area, leading to the formation of cracks in the material. As long as a uniform heating gradient is maintained, the laser beam can guide the generation of cracks in any desired direction.