Authoritative manual of surface treatment process of machined parts (I): Phosphating

Phosphating is a process of chemical and electrochemical reaction to form phosphate chemical conversion film, which is called phosphating film. The main purpose of phosphating is to protect the base metal and prevent the metal from corrosion to a certain extent; Used for priming before painting to improve the adhesion and anti-corrosion ability of paint film layer; It is used for antifriction lubrication in metal cold working process.

1. Basic principle:

The phosphating process includes chemical and electrochemical reactions. The phosphating reaction mechanism of different phosphating systems and materials is complex. Although scientists have done a lot of research in this area, it has not been fully understood so far. A long time ago, the phosphating film-forming mechanism was simply expressed by a chemical reaction equation:

8fe + 5me (H2PO4) 2 + 8H2O + h3po4me2fe (PO4) 2 · 4H2O (membrane) + me3 (PO4) · 4H2O (membrane) + 7fehpo4 (sediment) + 8h2 ↑

Me is Mn, Zn, etc. Machu et al. Believe that when steel is immersed in a high-temperature solution containing phosphoric acid and dihydrogen phosphate, it will form a crystalline phosphating film composed of phosphate precipitates, and produce monohydrogen phosphate iron sediment and hydrogen. The explanation of this mechanism is relatively rough and can not completely explain the film-forming process. With the gradual deepening of phosphating research, scholars agree that the phosphating film-forming process is mainly composed of the following four steps:

① The etching of acid reduces the H + concentration on the surface of the base metal

Fe – 2e→ Fe2+

2H2-+2e→2[H] (1)

H2

② Acceleration of accelerator (oxidant)

[O]+[H] → [R]+H2O

Fe2++[O] → Fe3++[R]

Where [O] is the accelerator (oxidant) and [R] is the reduction product. The accelerator oxidizes the hydrogen atom produced in the first step of the reaction, which accelerates the speed of reaction (1) and further leads to a sharp decrease in the concentration of H + on the metal surface. At the same time, Fe2 + in the solution is oxidized to Fe3 +.

③ Multistage dissociation of phosphate

H3PO4 H2PO4-+H+ HPO42-+2H+ PO43-+3H- (3)

Due to the sharp decrease of H + concentration on the metal surface, the dissociation equilibrium of phosphate at all levels moves to the right, and finally PO43 -.

④ Phosphate precipitates and crystallizes into phosphate film

When PO43 – dissociated from the metal surface and metal ions (such as Zn2 +, Mn2 +, Ca2 +, Fe2 +) in the solution (metal interface) reach the solubility product constant KSP, phosphate precipitation will be formed

Zn2++Fe2++PO43-+H2O→Zn2Fe(PO4)2·4H2O↓ (4)

3Zn2++2PO43-+4H2O=Zn3(PO4)2·4H2O↓ (5)

Phosphate precipitation and water molecules form phosphating crystal nucleus, and the crystal nucleus continues to grow into phosphating grains. Countless grains are closely stacked to form phosphating film.

The side reaction of phosphate precipitation will form phosphating sediment

Fe3++PO43-=FePO4 (6)

The above mechanism can not only explain the phosphating film-forming process of zinc series, manganese series and zinc calcium series, but also guide the design of phosphating formula and phosphating process. From the above mechanism, it can be seen that appropriate oxidant can improve the speed of reaction (2); Lower H + concentration can make the dissociation equilibrium of phosphate dissociation reaction (3) move to the right more easily and dissociate PO43 -; If there is active point surface bonding on the metal surface, the precipitation reaction (4) (5) can form phosphate precipitation nuclei without too much supersaturation; The production of phosphating sediment depends on reaction (1) and reaction (2). The high concentration of H + in solution and strong accelerator increase the sediment. Accordingly, in the actual phosphating formula and process implementation, the surface is: appropriate and strong accelerator (oxidant); High acid ratio (relatively low free acid, i.e. H + concentration); Adjusting the metal surface to have active points can improve the phosphating reaction speed and quickly form a film at a lower temperature. Therefore, the formulation design of low-temperature rapid phosphating generally follows the above mechanism, and selects strong accelerator, high acid ratio, surface adjustment process, etc.

About phosphating sediment. Because the phosphating sediment is mainly FePO4, in order to reduce the amount of sediment, we must reduce the amount of Fe3 +, that is, reduce the H + concentration of phosphating solution (low free acidity) and reduce the oxidation of Fe2 + to Fe3 +.

The phosphating mechanism of zinc and aluminum is basically the same. The phosphating speed of zinc material is fast, the phosphating film is only composed of zinc phosphate, and there is little sediment. Aluminum phosphating generally needs to add more fluorine compounds to form AlF3 and alf63 -. The phosphating step polymerization of aluminum is basically the same as the above mechanism.

2. Phosphating classification

There are many classification methods of phosphating, but it is generally classified according to phosphating film-forming system, phosphating film thickness, phosphating service temperature and accelerator type.

2.1 classification according to phosphating film system

According to the phosphating film-forming system, it is mainly divided into six categories: zinc series, zinc calcium series, zinc manganese series, manganese series, iron series and amorphous iron series.

The main components of zinc phosphating bath solution are: Zn2 +, h2po3 -, NO3 -, H3PO4, accelerator, etc. The main composition of the formed phosphating film (steel parts): zn3 (PO4) 2 · 4H2O, zn2fe (PO4) 2 · 4H2O. Phosphating grains are dendritic, acicular and have many pores. It is widely used in priming before painting, anti-corrosion and antifriction lubrication for cold working.

The main components of zinc calcium phosphating bath solution are Zn2 +, Ca2 +, NO3 -, H2PO4 -, H3PO4 and other additives. The main components (iron and steel parts) forming the phosphating film: zn2ca (PO4) 2 · 4H2O, zn2fe (PO4) 2 · 4H2O, zn3 (PO4) 2 · 4H2O. The phosphating grains are compact and granular (sometimes large acicular grains) with few pores. Used for priming and anti-corrosion before coating.

The main composition of zinc manganese phosphating bath solution: Zn2 +, Mn2 +, NO3 -, H2PO4 -, H3PO4 and other additives. The main composition of phosphating film: zn2fe (PO4) 2 · 4H2O, zn3 (PO4) 2 · 4H2O, (Mn, Fe) 5h2 (PO4) 4 · 4H2O. The phosphating grains are in the mixed crystal form of particle needle dendritic with few pores. It is widely used for priming before painting, anti-corrosion and antifriction lubrication for cold working.

The main composition of manganese phosphating bath solution: Mn2 +, NO3 -, H2PO4, H3PO4 and other additives. The main composition of phosphating film formed on steel parts is: (Mn, Fe) 5h2 (PO4) 4 · 4H2O. The phosphating film has large thickness, few pores and dense grains. It is widely used in anti-corrosion and antifriction lubrication of cold working.

The main composition of iron series phosphating bath solution: Fe2 +, H2PO4, H3PO4 and other additives. Main composition of phosphating film (iron and steel workpiece): fe5h2 (PO4) 4 · 4H2O. The phosphating film has large thickness, high phosphating temperature, long treatment time, many film pores and granular phosphating grains. It is used for anti-corrosion and antifriction lubrication of cold working.

The main components of amorphous iron series phosphating bath solution: Na + (NH4 +), H2PO4, H3PO4, MoO4 – (ClO3 -, NO3 -) and other additives. Main composition of phosphating film (iron and steel parts): Fe3 (PO4) 2 · 8H2O, Fe2O3. The phosphating film is thin, and the microstructure of the film is in the plane distribution of amorphous phase. It is only used for priming before painting.

2.2. Classification according to the thickness of phosphating film

According to the thickness of phosphating film (phosphating film weight), it can be divided into four types: sub lightweight, lightweight, sub heavyweight and heavyweight. The weight of sub lightweight film is only 0.1 ~ 1.0g/m2, which is generally amorphous iron phosphating film. It is only used for priming before painting, especially for workpieces with large deformation. The lightweight film weighs 1.1 ~ 4.5 g / m2, which is widely used for priming before painting, and is less used in anti-corrosion and cold processing industries. The thickness of the second heavyweight phosphating film is 4.6 ~ 7.5 g / m2. Due to the large weight of the film, the film is thick (generally > 3) μ m) It is less used as primer before painting (only as primer before painting of steel parts that are basically not deformed), and can be used for anti-corrosion and antifriction and lubrication in cold working. The heavyweight film weighs more than 7.5 g / m2 and is not used as primer before painting. It is widely used for anti-corrosion and cold processing.

2.3. Classification according to phosphating treatment temperature

According to the treatment temperature, it can be divided into four categories: normal temperature, low temperature, medium temperature and high temperature. Normal temperature phosphating is phosphating without heating. The general treatment temperature of low-temperature phosphating is 30 ~ 45 ℃. Medium temperature phosphating is generally 60 ~ 70 ℃. High temperature phosphating is generally greater than 80 ℃. The temperature division method itself is not strict. Sometimes there are sub medium temperature and sub high temperature methods, which depend on everyone’s wishes, but generally follow the above division method.

2.4 classification by accelerator type

Since there are only a few kinds of phosphating accelerators, it is helpful to understand the bath solution according to the types of accelerators. The phosphating treatment temperature can be generally determined according to the type of accelerator. For example, NO3 – accelerator is mainly medium temperature phosphating. Accelerators are mainly divided into nitrate type, nitrite type, chlorate type, organic nitride type, molybdate type and other main types. Each accelerator type can be used together with other accelerators, and there are many branch series. Nitrate types include: NO3 -, NO3 – / NO2 – (authigenic type). Chlorate type includes ClO3 -, ClO3 – / NO3 -, ClO3 – / NO2 -. Nitrite includes: nitroguanidine R – NO2 – / ClO3 -. Molybdate type includes MoO4 -, MoO4 – / ClO3 -, MoO4 – / NO3 -.

There are many classification methods of phosphating, such as phosphating of steel parts, aluminum parts, zinc parts and mixed parts according to material.

2、 Pretreatment before phosphating

In general, phosphating treatment requires that the workpiece surface should be a clean metal surface (two in one, three in one and four in one exceptions). Before phosphating, the workpiece must be pretreated with grease, rust, scale and surface adjustment. In particular, Phosphating for priming before painting requires surface adjustment to make the metal surface have a certain “activity”, so as to obtain a uniform, detailed and dense phosphating film and meet the requirements of improving the adhesion and corrosion resistance of the paint film. Therefore, phosphating pretreatment is the basis for obtaining high-quality phosphating film.

1. Degreasing

The purpose of degreasing is to remove grease and oil on the surface of the workpiece. Including mechanical method and chemical method. Mechanical methods mainly include: manual brushing, sand blasting, shot blasting, flame burning, etc. Chemical method mainly includes solvent cleaning, acid cleaning agent cleaning, strong alkaline solution cleaning and low alkaline cleaning agent cleaning. The following describes the chemical degreasing process.

1.1 solvent cleaning

Solvent method is generally used to remove grease by non flammable halogenated hydrocarbon vapor method or emulsification method. The most common is to use trichloroethane, trichloroethylene and perchloroethylene steam to remove grease. The steam degreasing speed is fast, the efficiency is high, the degreasing is clean and thorough, and the removal effect of all kinds of oil and grease is very good. Adding a certain emulsion into chlorinated hydrocarbons has a good effect both in soaking and spraying. Due to the toxicity of chlorinated halogens, the vaporization temperature is also high. Moreover, due to the emergence of new water-based low alkaline cleaning agents, solvent steam and lotion degreasing methods are rarely used now.

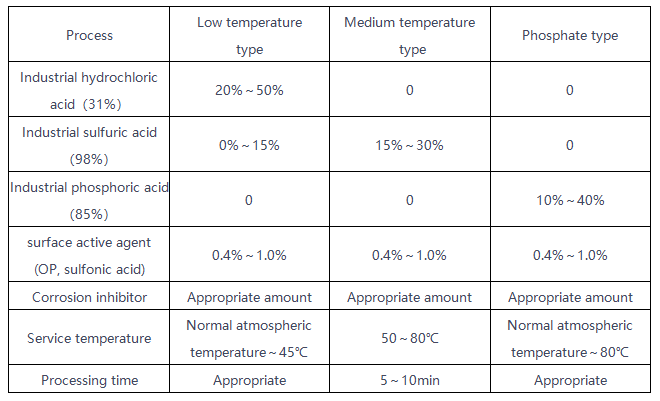

1.2 cleaning with acid cleaning agent

Acid cleaning agent is a widely used method to remove grease. It uses the emulsification, wetting and penetration principle of surfactant and the mechanical stripping effect of hydrogen produced by acid corrosion of metal to achieve the purpose of removing grease. Acid cleaning agent can be used at low and medium temperature. Generally, liquid oil can only be removed at low temperature, and oil and grease can be removed at medium temperature. Generally, it is only suitable for immersion treatment. Acid cleaning agent is mainly composed of surfactant (such as OP non-ionic surfactant and anionic sodium sulfonate), ordinary inorganic acid and corrosion inhibitor. Because it has the dual functions of rust removal and grease removal, it is used to be called “two in one” treatment solution. The formula and process parameters of common acid cleaning agents are shown in the table below.

Hydrochloric acid and sulfuric acid based cleaning agents are most widely used, with low cost and high efficiency. However, the residual Cl – and SO42 – in pickling do great harm to the post corrosion of the workpiece. The phosphoric acid group has no hidden danger of corrosive residue, but the cost of phosphoric acid is higher and the cleaning efficiency is lower.

For zinc parts, aluminum parts are generally not cleaned with acid cleaning agent, especially zinc parts corrode very quickly in acid.

1.3 cleaning with strong alkaline solution

Strong alkaline solution is a traditional and effective method to remove grease. It uses the saponification reaction of strong alkali to vegetable oil to form saponified matter dissolved in water to achieve the purpose of removing oil. Pure strong alkaline solution can only saponify and remove vegetable oil, but not mineral oil. Therefore, people use the emulsification of surfactants to remove mineral oil by adding surfactants, generally sulfonic acid anionic surfactants, to strong alkali solution. The use temperature of strong alkali liquid for grease removal is high, usually > 80 ℃. The common strong alkali cleaning formula and process are as follows:

Sodium hydroxide 5% ~ 10%

Sodium silicate 2% ~ 8%

Sodium phosphate (or sodium carbonate) 1% ~ 10%

Surfactant (sulfonic acid) 2% ~ 5%

Treatment temperature > 80 ℃

Treatment time: 5 ~ 20min

The treatment methods are soaking and spraying

Strong alkali liquid degreasing requires high temperature, high energy consumption, high corrosion to equipment, and the material cost is not low. Therefore, the application of this method is gradually decreasing.

1.4 cleaning with low alkaline cleaning solution

Low alkaline detergent is the most widely used degreasing agent at present. Its alkalinity is low, and its general pH value is 9 ~ 12. It has less corrosion to the equipment and less damage to the surface state of the workpiece. It can be used at low and medium temperatures with high grease removal efficiency. Especially when used in spray mode, the grease removal effect is particularly good. Low alkaline cleaning agent is mainly composed of inorganic low alkaline additives, surfactants, defoamers, etc. Non model additives are mainly sodium silicate, sodium tripolyphosphate, sodium phosphate, sodium carbonate, etc. Its function is to provide a certain alkalinity and have the function of dispersion and suspension. It can prevent the removed grease from being adsorbed on the workpiece surface again. Surfactants are mainly non-ionic and anionic, generally polyvinyl chloride OP and sulfonate, which play a major role in the process of oil removal. When there are special requirements, some other additives need to be added. For example, defoamer and sometimes surface conditioner need to be added during spraying, which has the dual functions of degreasing and surface adjustment. There are many commercial products of low alkaline cleaning agents, such as pa30-im, pa30-sm, fc-c4328, pyroclean 442, etc.

The commonly used low alkaline cleaning solution formula and process are as follows:

Immersion spray

Sodium tripolyphosphate 4 ~ 10g / L

Sodium silicate 0 ~ 10g / L 0 ~ 10g / L

Sodium carbonate 4 ~ 10g / L

Defoamer 0.5 ~ 3.0g/l

Surface conditioner 0 ~ 3 g / L 0 ~ 3 g / L

Free alkalinity 5 ~ 20 points 5 ~ 15 points

Treatment temperature: normal temperature ~ 80 ℃ 40 ~ 70 ℃

Treatment time: 5 ~ 20min, 1.5 ~ 3.0min

The main attention of immersion cleaning agent is the cloud point of surfactant. When the treatment temperature is higher than the cloud point, the surfactant precipitates and floats up, making it lose the degreasing ability. Generally, it can be solved by adding anionic surfactant. Sufficient defoaming agent shall be added to the spray cleaning agent, and it is particularly important that no foam is generated during spraying.