Application of CimatronE software in five axis die processing and product processing

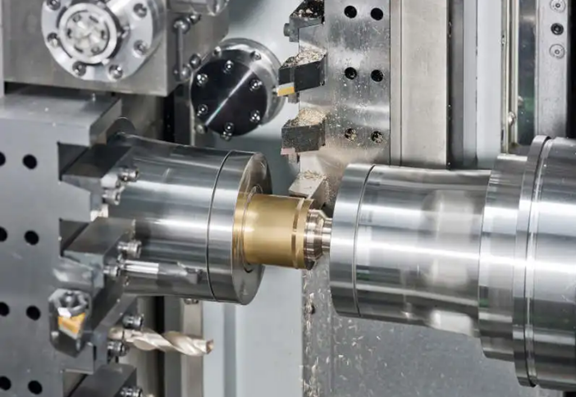

With the continuous innovation and breakthrough of numerical control technology, five axis machining is adopted by more and more industries, such as aerospace, electric power, shipbuilding, high-precision instruments, mold manufacturing and so on. However, the automatic programming software plays a key role in the five axis machining technology, because the process layout of the tool path, the interference inspection between the tool collet and the workpiece or the fixture, and the identification of the blank residue are all automatically considered by the software, and the programmers can not achieve it through calculation. They just optimize the cutting parameters according to experience to get a more reasonable and effective machining path.

CimatronE software is one of the most intelligent and efficient software in today’s five axis machining technology. It has special solutions for complex five axis molds and five axis product processing.

1、 In terms of mold processing:

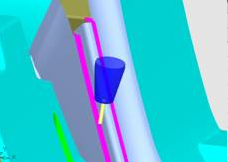

1. Using blank residue knowledge and blank quick preview function, automatically identify the residue after each processing, optimize the tool path, safe and efficient; The machining results can be quickly observed without calculating the tool path program, which is convenient for repeated optimization of parameters. After the results meet the requirements, the final one-time error free calculation can be carried out to save programming time (Fig. 1 and Fig. 2).

2. Automatic calculation of the shortest tool length can make rational use of tools and save costs.

3. Based on the processing of slope analysis technology, the slope of the surface is automatically analyzed and the surface is calculated into flat area and steep area. Realize different cutting methods in different areas to realize compound machining.

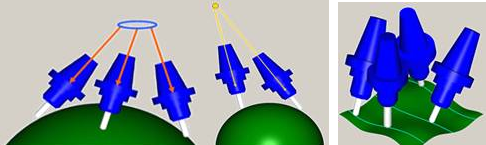

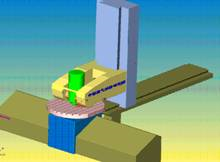

4. Automatically consider the interference of tool chuck and carry out three-axis cutting in the area without interference (Fig. 3); In case of interference due to insufficient tool length, the automatic swing angle realizes five axis linkage machining (Fig. 4).

5. Realize the five axis root cleaning function and combine it with blank residual knowledge, which is efficient and safe; The second roughing option is used to homogenize the residual blank at the fillet, so as to solve the problem of tool breakage caused by too much scrap due to the large diameter of the root cleaning tool and the previous tool (Fig. 5).

6. It is fully integrated with CAD to facilitate the modification and editing of curves, surfaces and entities without data conversion.

2、 In terms of product processing:

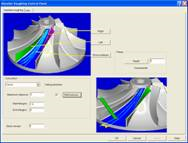

1. There is a special five axis machining strategy for special parts, such as impeller, blade and elbow, to realize five axis linkage rough machining, finish machining and fillet cleaning (Fig. 6).

2. The correct and safe tool axis tilt control can carry out the tool walking according to the point, curve, coordinate axis and surface UV line direction. At the same time, based on the algorithm of tool contact point, it can avoid zero speed cutting and improve the surface quality (Fig. 7).

3. Multi axis blank function. When the workbench or tool rotates by an angle, it can automatically identify the blank in the current coordinate system, cut evenly and safely, reduce empty tools and improve efficiency.

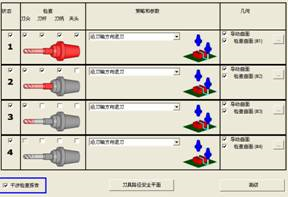

4. The interference inspection of intelligent blade, tool bar and tool handle is reflected to the user in the form of report (Fig. 8).

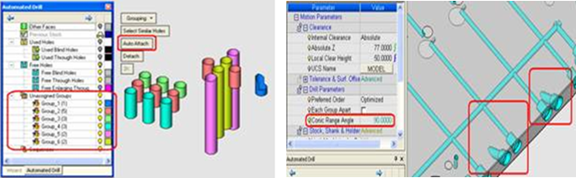

5. Fast five axis drilling function. According to the set angle limit, it can automatically identify the shape and position of the hole without user selection; After the hole position is determined, the shape and size parameters of the hole are automatically displayed, which is conducive to users’ proofreading and editing; At the same time, the system is grouped uniformly to facilitate user editing and modification (Fig. 9).

6. Powerful background auxiliary function. Support post-processing of all international control systems and user-defined formats; Support the machine tool simulation of tool path and the machine tool simulation of reverse reading post-processing code (FIG. 10).

To sum up, CimatronE’s five axis processing function has high intelligence, safety and efficiency. It provides rich processing strategies for the processing of complex molds and products. It is easy to learn and use. It is a powerful and comprehensive five axis processing software.