Analysis on the Causes of Bolt Fracture

1. Reasons for bolt breakage:

1. It is caused by the materials of bolts. If the materials we choose are better, then the quality of our bolts will be better. If the materials we choose are relatively poor, our bolts will break more to a certain extent.

2. The strength of the bolt is not high enough. If the pressure that the bolt is under is greater than the strength of the bolt, the bolt will easily break. Therefore, when using the bolt, we’d better understand the strength that the bolt can withstand, so that we can choose the bolt with higher strength, and the probability of bolt fracture will be reduced.

3. It is caused by unqualified manufacturing. Many bolts will be produced unqualified, so there is no way to play the quality of standard bolts, which will lead to the fracture of bolts to a certain extent. After the production of bolts, we must pass the inspection to ensure that the bolts are qualified before they are sold, which is also the most basic guarantee for consumers.

4. It is caused by the fatigue strength of the bolt. The most important factor for the bolt to break is the fatigue strength of the bolt. At the beginning, there was no problem when we used bolts, but after the operation of objects, there might be a certain degree of looseness. Continuing the operation when loosening will increase the fatigue strength of the bolts. When the limit of the range that the bolts can withstand is reached, the bolts will break.

2. Measures to prevent bolt breakage:

1. Add sizing block

2. Improve bolt processing technology

3. Improve the standard section processing technology

3. The quality of bolts is determined by the length, specification, category, connection form and other conditions of bolts.

4. The pretightening torque of the bolt makes the bolt subject to tensile stress and shear stress. The control of the pretightening force is to ensure that the flange connection system operates in a tight, safe and reliable way for a long period of time. The gasket surface must have sufficient sealing specific pressure. In particular, under high temperature conditions, the gasket will have aging, creep relaxation, and flange and bolt will have thermal deformation. Therefore, the sealing of the high temperature connection system is much more difficult than under normal temperature, At this time, the application and control of bolt pre tightening force is very important, and too large or too small pre tightening force will adversely affect the sealing. If the bolt pre tightening force is too large, the sealing gasket will be pressed to death and lose its elasticity, or even the bolt will be twisted off; Too small bolt pre tightening force makes the residual compression stress on the gasket surface after compression less than the working seal specific pressure, which leads to leakage of the connection system. Therefore, how to control the bolt pretightening force is a problem that must be paid attention to in production practice.

5. The tensile strength and yield strength of bolts determine the strength of bolts. The greater the strength, the longer the service life.

6. Fatigue strength of bolts. It is related to the dangerous section area, the maximum and minimum stress of the bolt, the bolt stress amplitude, and the average bolt stress.

7. Overload failure of bolts refers to sudden and instantaneous fracture during service. This failure has no obvious sign in advance, so its harm is serious.

Overload failure characteristics:

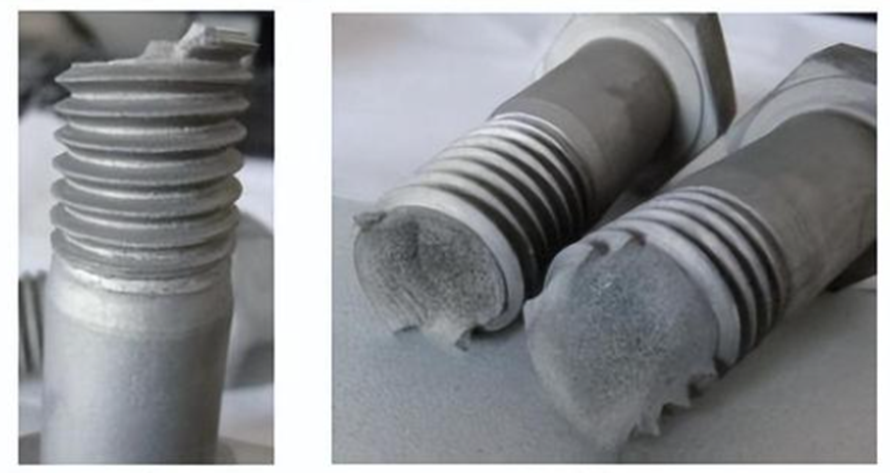

High strength bolts are widely used in hydropower plants. In fact, the thread on the bolt is the same as the notch, and the stress concentration factor is high. When it fits with the nut, the stress concentration factor is further improved. For bolts that transmit load by compressing nuts, the stress is most concentrated at the first thread close to the bearing surface of nuts. In addition, due to the structural characteristics of the bolt, the stress at the junction of the head and the rod is relatively concentrated. Therefore, the overload failure of the bolt causes its fracture in these two parts.

8. Stress corrosion of high-strength bolts:

(1) Conditions for stress corrosion

There must be tensile stress. The greater the tensile stress, the shorter the time required for fracture. The stress required for fracture is generally lower than the yield strength of the material. The tensile force of bolts in service and the pre tightening force in assembly are the conditions that cause stress corrosion.

(2) There must be corrosive media sensitive to materials

When stress and corrosion medium form a system, the defects of stress corrosion cracking can occur in materials.