All you want about stamping die is here (I)

1、 Information from waste

The scrap is essentially the reflection of the formed hole. The opposite position is the same. By checking the scrap, you can judge whether the gap between the upper and lower dies is correct. If the gap is too large, the waste will have rough and undulating fracture surfaces and a narrow bright zone. The larger the gap, the greater the angle between the fracture surface and the bright zone area. If the gap is too small, the waste will show a small angle fracture surface and a wide bright band area.

The excessive gap forms a hole with large curl and edge tear, so that a thin edge of the section protrudes slightly. Too small gap forms a band with slight crimping and large angle tearing, resulting in the profile being more or less perpendicular to the material surface.

An ideal waste should have reasonable collapse angle and uniform bright band. This keeps the impulse pressure to a minimum and forms a clean round hole with few burrs. From this point of view, extending the service life of the die by increasing the gap is in exchange for sacrificing the quality of the finished hole.

Two, the choice of mold clearance

The clearance of the die is related to the type and thickness of the material being punched. Unreasonable clearance can cause the following problems:

(1) If the gap is too large, the burr of the stamped workpiece is relatively large and the stamping quality is poor. If the gap is too small, although the punching quality is good, the wear of the die is serious, which greatly reduces the service life of the die and is easy to cause the breaking of the punch.

(2) If the gap is too large or too small, it is easy to produce adhesion on the punch material, resulting in material belt during stamping. Too small gap is easy to form a vacuum between the bottom surface of the punch and the sheet metal, resulting in waste rebound.

(3) Reasonable clearance can prolong the service life of the die, have good unloading effect, reduce burr and flanging, keep the plate clean, the hole diameter is consistent, and will not scratch the plate, reduce the grinding times, keep the plate straight and accurate punching positioning.

Please refer to the following table to select the die clearance (the data in the table is percentage)

26e90001fd75ee9cec5d

3、 How to improve the service life of die

For users, improving the service life of the die can greatly reduce the stamping cost. The factors affecting the service life of the die are as follows:

1. Type and thickness of materials;

2. Whether a reasonable lower die clearance is selected;

3. Structural form of mould;

4. Whether there is good lubrication during material stamping;

5. Whether the mold has undergone special surface treatment;

6. Such as titanium plating, carbon titanium nitride;

7. Alignment of upper and lower turrets;

8. Reasonable use of adjusting gasket;

9. Whether the inclined edge die is properly used;

10. Whether the die base of the machine tool has been worn;

4、 Problems needing attention in punching special size holes

(1) Minimum hole diameter: punching φ 0.8—— φ 1.6 please use a special punch for punching within the range.

(2) When punching thick plates, please use a larger die relative to the processing hole diameter. Note: at this time, if the normal size die is used, the punch thread will be damaged.

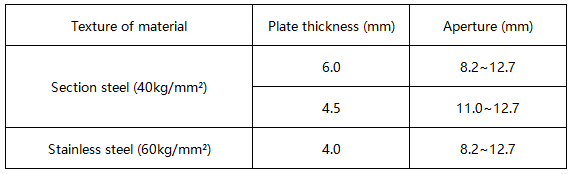

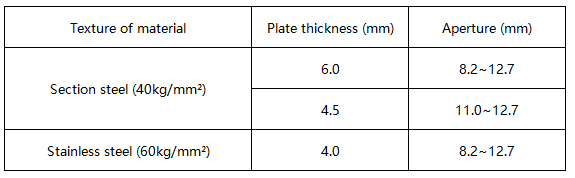

Example 1. According to the processing conditions in the following table, although the processing aperture corresponds to the die in station a, please use the die in station B.

Example 2. According to the processing conditions in the following table, although the processing aperture corresponds to the die in station B, please use the die in station C.

(3) The ratio of the minimum width to the length of the punch edge shall not be less than 1:10.

Example 3. For rectangular punch, when the cutting edge length is 80mm, the cutting edge width ≥ 8mm is the most appropriate.

(4) The relationship between the minimum dimension of the cutting edge of the punch and the plate thickness. It is suggested that the minimum dimension of the cutting edge of the punch should be 2 times of the plate thickness.