Accurate Adjustment Parameters for Vibration Analysis of High Speed Machine Tools

Vibration analysis is a very important aspect of testing the performance of machining centers, but it is also a missing aspect at present. If this analysis has not been carried out on high-speed machine tools, the machine tool manufacturers may not know what the machine tools can do.

In the process of milling, experienced machinists and NC programmers will react to the harsh and unpleasant sound caused by poor cutting conditions. This is due to the fact that the selected cutting parameters are not ideal enough. Facing this situation, they will reduce some parameters. In other words, they will lower some process parameters.

Some of the specific parameters they reduce may be the cutting depth, or a combination of speed and feed rate, or even the cantilever length of the tool. Regardless of the parameter, “down regulation” is a flexible strategy to obtain better machining performance. The experienced processing personnel are very skilled in adjusting these parameters, and they can reduce these parameters to the extent necessary to achieve an acceptable cutting level. In most processing workshops, this method of reducing processing parameters – this compromise scheme – is seen as a correct response of the operator.

However, in high speed machining, this method of reducing machining parameters is not the correct solution. In fact, people even find that this practice is contrary to the essence of high-speed machining.

Parameters themselves are very important, such as cutting depth, spindle speed and tool length will affect the processing performance. However, when the chattering sound of a high-speed machine tool reflects the poor performance of the machine tool, “lowering” the parameter may be counterproductive. There are many workshops that use high-speed machining centers, which waste their actual production capacity in vain, and ultimately cannot achieve the production goals.

In the application field of high-speed machining, in order to achieve more stable cutting, many manufacturers may still need to adopt the method of parameter “down regulation”, but there is a more effective method, that is, the method of parameter “up regulation”. If the two parameters of spindle speed and tool length are involved at the same time, the better answer to deal with chatter is to improve one of them. Although it seems strange, practical experience shows that higher spindle speed and lower rigidity tools, or only one of them, can allow the machine tool to handle more aggressive cutting depth, because these changes make the vibration tendency of the system more harmonious. All processing workshops that recognize this point can understand the true essence of high-speed machining, that is, working within the spindle speed range, can not be determined only by intuition or experience, and there are different ideal cutting conditions under different circumstances. Now there is a machining workshop that knows this very well. This workshop is a branch of Warner Robins Air Force Base in Georgia.

Milling in Military Industry

This workshop capable of rapid response is a division of the 573 Product Maintenance Squadron of the 402nd Maintenance Battalion of the Air Force. The tasks of this workshop include the processing of replacement spare parts for fighter aircraft and transport aircraft. It is responsible for the processing of replacement parts for all aircraft flying to this base all over the world. The maintenance here is very frequent, because these aircraft need to return to the action status quickly, so the workshop often needs to produce some complex and critical parts in small batches according to the limited delivery time requirements.

Programmers Mr. David Devore and Mr. Mike Estes said that at first, when this workshop began to use high-speed machining centers, they knew nothing about it, so the use efficiency of the machine tool was very low at that time. When these machines are used for machining, the cutters are often broken, including 3/4in (1in=25.4mm) end milling cutters. From the reaction of this workshop, we can only slow down the cutting speed of some processing items.

The processing workshop of Warner Robins started to investigate the milling process using resonance frequency after purchasing its highest speed high-speed machine tool

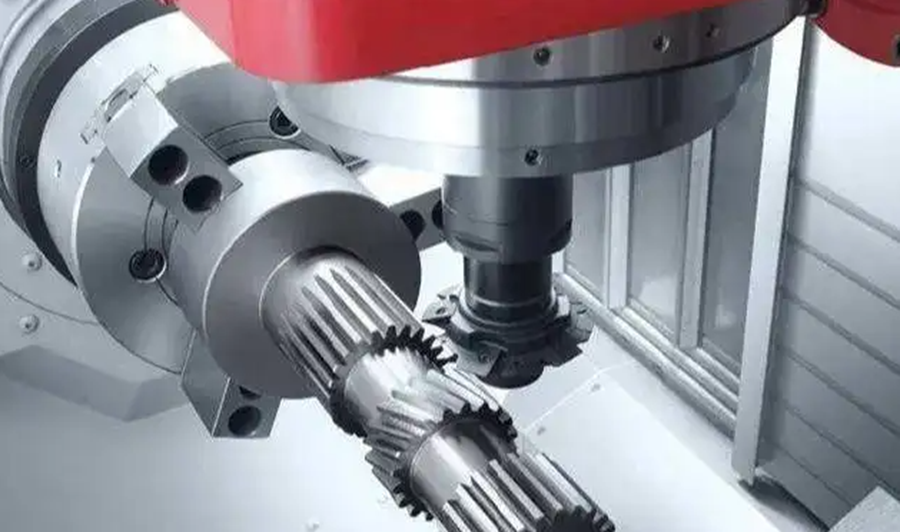

However, when the workshop introduced and installed its MAG3 high-speed machining center with a maximum speed of 30000 r/min from Makino, they conducted a “knock test” on the machine tool. In other words, the workshop uses a sensitive hammer to strike the tools installed in the spindle like a bell to test the vibration characteristics of the machine tool.

For a specific combination of machining center, tool shank and milling cutter, the “knock test” can be used to find the spindle speed and cutting depth that can make the metal cutting speed reach the highest. The purpose of this analysis method is to find out the stable cutting speed of each tool or tool shank used on a specific machine tool after debugging. In Robins, once these stable parameters are found, they will use them in new machine tools, thus improving the processing quality, productivity and tool life of the parts in the workshop, and all the indicators exceed the level of high-speed milling. Because the gap is so large, the workshop decided to carry out the same analysis and test on its existing high-speed machine tools. On these machine tools, the workshop found that when it runs at a relatively high speed and exceeds the speed that the workshop has been running before, the work of many tools is more stable, more effective and safer. After the machine is started, its speed shall be consistent with these optimal parameters. The workshop immediately starts to work more quietly. The cutting amount increases, the processing quality of parts improves, and the tool is not broken.

Warner Robins Air Force Base serves cargo aircraft and fighter aircraft.

The machining workshop supports this mission

Now, the workshop starts to use the parameters obtained from vibration analysis to run high-speed machine tools. When exceeding a certain speed, the workshop realized that this kind of analysis was actually crucial to the overall benefit of the machine tool.

The reason is related to the resonance frequency. Each special combination of machine tool, tool handle and tool has a specific stable speed value, which allows the machine tool to achieve the maximum cutting depth and metal cutting amount. Then there are more explanations, but for now, it is enough to explain the problem, but it is impossible to infer these speed values from experience. For Robins, there is no practical method to find stable parameters through trial cutting, because many tools are often used in this workshop. Therefore, the workshop has signed a contract with an outsourcing partner, which can help the workshop quickly measure the vibration of all machine tools, and then determine the optimal speed and cutting depth according to the combination of each tool or tool handle used daily by the machine tool.

Tool Dashboard

Programmers say that the cutting performance can be basically the same now. In particular, the environment of the workshop has changed greatly. Because of the reduction of vibration, the processing environment in the workshop is very quiet. Moreover, because high-speed machine tools can perform deep and powerful cutting at a higher speed without tool breakage, the machine tools have higher production efficiency. In addition, now it can provide information about the best processing parameters, so the productivity of programmers themselves is further improved. One of the resources now available to them is the “Tool Dashboard”, which allows these programmers to accurately predict the characteristics and productivity of any cutting parameters selected and set for a particular milling tool path.

From here, it can be seen that the technicians are installing a newly processed part on the wing of the aircraft. Now, when the tools and tool handles used in one of the high-speed machining centers are selected, the best parameters can be selected according to their conditions. In fact, the parameters obtained from the vibration analysis will be automatically input into Catia. When these cutting conditions need to be adjusted, if the cutting depth may not meet the cutting requirements, the relevant parameters can be controlled through the tool dashboard to find another group of effective cutting conditions to eliminate the source of chatter. Even the feed speed can be adjusted in this way, that is, it can be tested according to the bending moment of the spindle.

On the “Speed” table of the tool dashboard, the green area represents the stable cutting area of this particular tool.

The tool dashboard allows programmers to easily control the speed, cutting depth and cutting load, and predict the impact of these changes according to the dynamic changes of the machine tool

Warner Robins signed a contract with BlueSwarf to conduct “knock test analysis” and provide tools dashboard.

BlueSwarf is an enterprise specializing in machine tool vibration analysis and test. The company sells “Metalmax” analyzers to some processing workshops for internal analysis of workshops, but the company also conducts analysis and measurement on site for processing workshops that contract analysis to outsourcing units. The actual test is simply to strike the tool running in the machining center, that is, to strike the tool with a sensitive hammer, and then capture the feedback information through the sensor on the tool tip. Since different combinations of tools and toolholders need to be tested separately, the entire analysis test may take several hours or days. The details of some tools, such as the fillet radius, have no relationship with the test results, so not every actual data of every tool must be tested. Nevertheless, the machining workshop of Warner Robins still needs to test the setting values of 45~50 tools on each high-speed machine tool.

Specific speed

So why does a machining center need to do this? Why does a machining center work better at a specific speed or with a tool of a specific length? This answer is related to the fact that every mechanical system has several groups of natural vibration frequencies, and machining centers, tool holders and tool systems are no exception. The system has these natural frequencies, and to some extent, it will vibrate according to these frequencies during its cutting. At the same time, microwave effect will appear on the machined surface. These fluctuations may have a slight impact on the machining tool path. Moreover, this may also affect the feedback mechanism and damage the cutting process.

This stability legend shows that it is possible to increase the cutting depth in the whole speed range and in the specific narrow spindle speed band. The purpose of knock test is to find out these stable speeds. The machine tool has encountered such surface fluctuations during cutting. This fluctuation will cause the change of the cutting depth, as a result, the load on the tool will also fluctuate. This fluctuation is usually insignificant, so the response of the machine tool is also very small. However, in the process of strong cutting, the degree of vibration will become more obvious. In fact, the fluctuation itself will also generate driving force. The deflection of the tool will cause greater ripples, which will increase the degree of vibration in the cutting depth. This self-excited vibration is actually called “chattering”. The service life of the tool and the processing quality of the parts will be affected, and the noise will be more unbearable.

A different possibility is set where the spindle speed exceeds about 10000r/min. At a higher speed, it is possible to make some cutting speed when the blade contacts the workpiece consistent with the natural frequency of the system.

When this happens, the machine tool is still vibrating, but the tool tip basically moves with the ripple. At this time, the cutting load is uniform and the cutting is very smooth. For many workshops, this result is a very strange phenomenon. Some spindle speeds with very high specific speeds can allow them to achieve higher cutting depths at higher or lower speeds.

This problem can be explained. In the whole spindle speed range seen here, the peak value indicates the higher production cutting efficiency that can be achieved by this specific machine tool and tool setting. Areas with cross hatches indicate where chatter occurs. Therefore, when the rotating speed is 17792r/min, it is possible to perform stable cutting with extra large cutting depth. If the machine tool’s operating speed is slightly higher or lower than this value, even if the same level of power milling is not achieved, it is possible. In fact, any workshop that does not know this magic speed will not know what its machining center can do.

In the above picture, the computer shows the test of the two cutters. The test was initially carried out in the workshop of Robins Company. Only a few minutes after the test, we can see the different performance of the two cutters. The red peak value indicates the cutting depth that can be reached with a shorter tool, while the blue peak value behind it indicates the larger cutting depth that can be reached with a longer tool. In fact, the workshop may not know what its tool can do.

The magical characteristics of the tool

The difference of tool performance reveals a more potential surprising fact in high-speed machining. When BlueSwarf carried out knock test on Warner Robins’ oldest high-speed machining center, it found the phenomenon shown in. Generally speaking, shorter tools can perform milling more stably, but this is not always the case. On this specific machine tool, when two longer tools are used, it is found that the system can actually work more stably and reach a larger cutting depth. The debugging settings of the tools are shown in. On this particular machine tool, the higher the flexibility of the tool, the higher the metal cutting speed.

This workshop has used this machine tool for many years, and its working performance is good. Of course, the relevant information has provided great help. Over the years, the performance of the machine tool has been relatively good. Without such valuable information, it is impossible to achieve the goal of twice the result with half the effort. In other words, the potential output and quality of the machine tool will decline.