NC multi part machining solution for shouldered stainless steel nut

1. Processing characteristics of shoulder nut

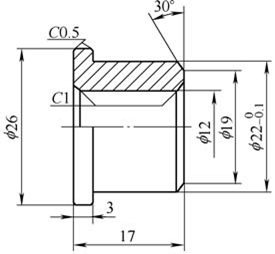

The shoulder stainless steel nut blank is shown in Figure 1. This kind of part has large processing quantity, small volume and short processing time. The operator needs to clamp repeatedly when processing on the ordinary horizontal lathe, resulting in the increase of auxiliary time, labor intensity and low processing efficiency. In order to reduce the machining efficiency and improve the machining process.

2. Process improvement

The process of processing the shoulder nut with an ordinary horizontal lathe is as follows: ① material preparation and quenching and tempering. ② Turning end face, turning outer circle, drilling, chamfering and cutting. ③ Turn the other end face to the total length, chamfering and tapping.

From the above process, it can be seen that the production of such a workpiece by ordinary horizontal lathe needs to be clamped twice, with complex processes and low efficiency.

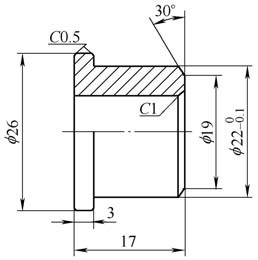

Improve the processing technology and transplant the processes completed on the ordinary horizontal lathe to the NC lathe, as shown in Figure 2. The NC lathe process is: ① material preparation and quenching and tempering. ② The whole shape, length, end face and chamfer are completed at one time. ③ The fitter taps the thread with a vertical drill.

The biggest advantage of CNC lathe is that each clamping can complete the processing of three workpieces, and the lathe tapping is handed over to the fitter through the vertical drilling machine. It can be seen that the new process can indeed improve production efficiency, reduce production costs and reduce labor intensity.

3. NC machining

NC machining is the core content of this process improvement, which mainly optimizes NC programming. During programming, the instruction M00 pause function and the instruction M98 call subroutine function are used, and the workpiece coordinate system functions of g54, G55 and g56 are used to realize the purpose of multi piece machining. NC machining is divided into the following processes:

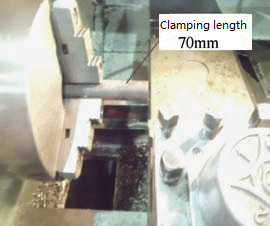

(1) Clamp. Before programming, we must choose a reasonable clamping mode. Because it is bar blanking processing, the fixture selects the three claw self centering chuck provided by the lathe. The clamping method is shown in Figure 3. The bar material shall extend 70mm outside the three claw self centering chuck foot (this is the position of the main program g54g00x19z0.2, and then the blank end face can be clamped against the clamping reference of the flat tool).

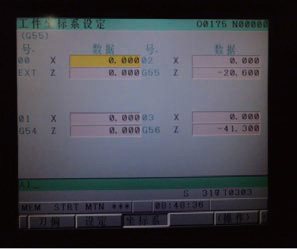

(2) NC programming. The programming adopts the method of main program and calling subroutine to realize multi piece machining. First, you need to set the workpiece coordinate system. The setting of workpiece coordinate system is shown in Figure 4. The origin of workpiece coordinate system g54 is x0 Z0, which is used for the processing of the first product. The origin of workpiece coordinate system G55 is x0 z-20.6, which is used for the processing of the second product. The origin of workpiece coordinate system g56 is x0z-41.3, which is used to process the third product.

The next step is to write NC machining program. The NC machining program is divided into two parts:

① The main function of the main program is to extend the length of the workpiece, set the tool, pause, select the workpiece coordinate system and call the subroutine. ② Subroutine, the main function is to process the contour, inner hole and chamfer of a single part. The program code is as follows.

Main program: o0176 (program number)

N1 G99, N2 t0101 (tool setting of cylindrical cutter), N3 g54 G00 X19 Z0 2. N4 M00 (pause), N5 G00 X100, N6 M00 (pause), N7 g54 M98 p0175, N8 G55 M98 p0175, N9 g56 M98 p0175, N10 M30

Subroutine: o0175 (program number)

N1 G99, N2 t0101 (cylindrical knife), N3 M03 S800, N4 M08, N5 G00 x30, N6 Z0, N7 G01 X5 F0 2、N8 X1 F0. 1、N9 X-2 F0. 05、N10 G00 X24、N11 G01 Z-14 F0. 2、N12 X25、N13 G00 Z0、N14 G01 Z-1.5 X22 F0. 15、N15 Z-14 F0. 25、N16 X24. 5. N17 z-14.9 x26, N18 z-21, n19 G00 X100, N20 z200, N21 t0303 (borehole), N22 M03 S300, n23 G00 x0, n24 Z2, N25 G01 Z-3 F0 1、N26 G74 R0. 5、N27 G74 Z-22 Q8000 F0. 1. N28 G00 z200, n29 T0202 (chamfering cutter), N30 M03 S500, N31 G00 X12, N32 Z1, N33 G01 Z-1 F0 1. N34 G00 z300, N35 t0404 (cutter), N36 M03 S800, n37 G00 x28, N38 Z-20, n39 G01 X25 F0 05、N40 X26、N41 Z-19、N42 X25 Z-20、N43 X10、N44 G00 X100、N45 Z200、N46 M05、N47 M09、N48 T0101、N49 M99

(3) Set the knife. Tool setting is the key step of NC machining. The accuracy of tool setting directly determines the quality of products. The reserved length during clamping is 70mm. In fact, this length is not measured. This is the main program g54g00x19z0 2. The specific implementation method is to adjust the programming origin of the first workpiece to (x0, z70). When the operator presses the start key, the main program runs, the machine tool quickly moves to the coordinate system g54 (X19, z0.2), and the program stops. At this time, the distance between the tool and the three jaw self centering chuck is just 70mm. The operator can directly pull the bar out of the tool and contact the tool tip. Then press the start key again to make the x-axis direction deviate from the workpiece by a distance greater than the diameter direction (that is, the main program g00x100 tool offset will not affect the clamping), the program stops and clamps the workpiece of the three jaw self centering chuck. Then press the start key to start processing the first part, and the second and third parts are processed automatically. After a group of parts are processed, press the start key again, and the machine tool returns to the tool setting point of the first part to start the next group of tool setting, and then cycle according to this. This tool setting method for bar processing can avoid the error caused by the operator during measurement, ensure the product processing quality, fast clamping speed and high efficiency.

4. Conclusion

Before the process improvement, it takes 4min to process a shoulder nut blank on an ordinary horizontal lathe. After the process improvement, three can be processed every 5 minutes on the NC lathe.

It can be seen that after the process improvement, the efficiency is increased by more than 50%, the labor intensity is reduced, and the product qualification rate is also improved, which has been highly praised by the operator. In fact, this optimized programming technology can be popularized and applied in machining. In machining, when the precision of parts is high and the axial length is small, this machining method can be used, and more parts can be processed at one time. It is more practical in bar material processing for production units focusing on small piece processing. This process method has been verified in the processing of many products.