Stamping process

What is stamping?

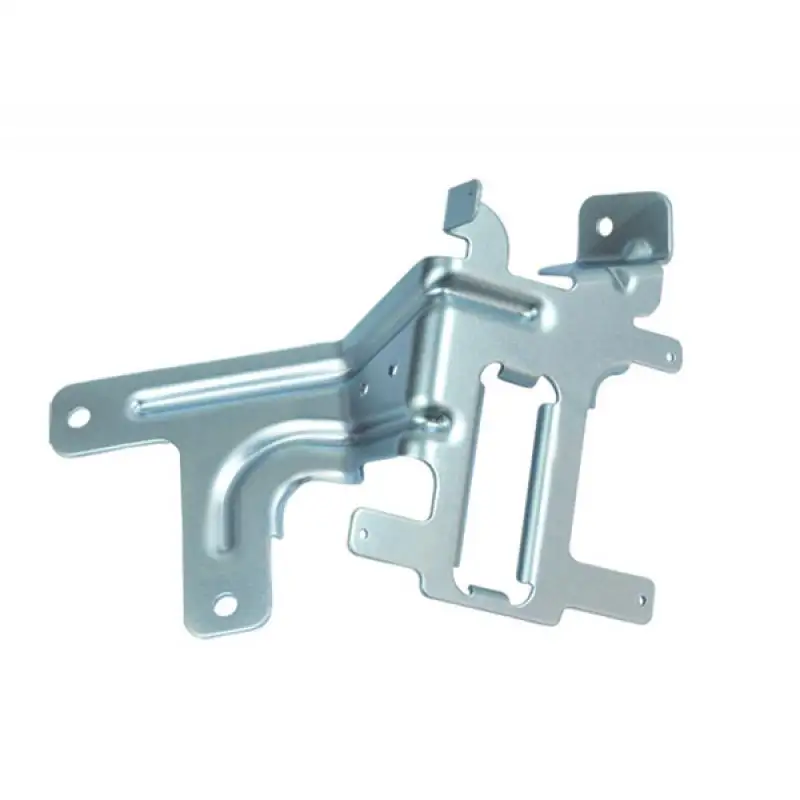

Stamping is a forming processing method of workpieces (stamping parts) with required shape and size by applying external force on plates, strips, pipes and profiles by press and die to cause plastic deformation or separation.

The car body, chassis, fuel tank, radiator sheet, boiler drum, container shell, motor, electrical iron core silicon steel sheet, etc. are all processed by stamping. Instruments, household appliances, bicycles, office machinery, household utensils and other products also have a large number of stamping parts.

According to the stamping processing temperature, it can be divided into hot stamping and cold stamping. The former is suitable for sheet metal processing with high deformation resistance and poor plasticity; The latter is carried out at room temperature, which is a common stamping method for thin plates.

Sheet metal, die and equipment are the three elements of stamping processing.

Sheet metal: The surface and internal properties of the sheet metal used for stamping have a great impact on the quality of the finished stamping products.

6 points for requirements of stamping materials

① The thickness is accurate and uniform.

② The surface shall be smooth and clean without spot, scar, scratch, surface crack, etc. Prevent scrap generation.

③ The yield strength is uniform without obvious directivity. In order to reduce defective products or waste products

④ High uniform elongation. To prevent uneven deformation.

⑤ Low yield ratio. In order to improve the accuracy of bending parts.

⑥ Low work hardening. To prevent future deformation

Die: The precision and structure of die directly affect the forming and precision of stamping parts. Die manufacturing cost and life are important factors that affect the cost and quality of stamping parts.

equipment

According to the transmission structure: manual punch, mechanical punch, hydraulic punch, pneumatic punch, high-speed mechanical punch, CNC punch

According to machining accuracy: ordinary punch, precision punch

According to the scope of use: ordinary press, special press

Processing characteristics

1. The stamping process has high production efficiency, convenient operation, and is easy to realize mechanization and automation.

2. The stamping quality is stable, the interchangeability is good, and it has the characteristics of “identical”.

3. Stamping strength and stiffness are high.

4. The cost of stamping parts is low.