Why does the prototype need to be polished

Functions of hand model grinding:

(1) Remove burrs, oil and dust on the surface of the substrate

(2) Reduce the roughness of the workpiece surface:

(3) Enhance the adhesion of the coating.

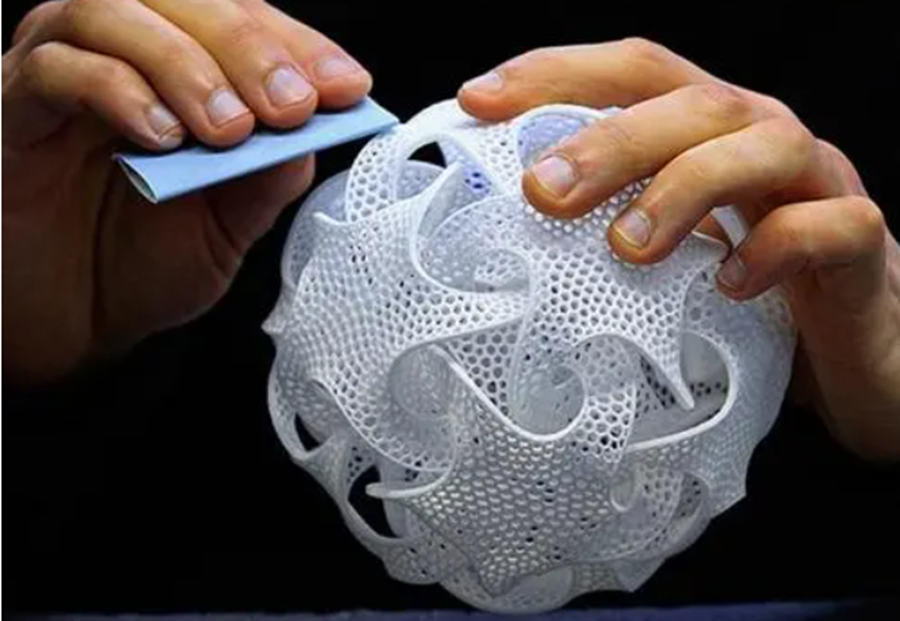

1. Manual grinding and polishing

The efficiency is low, the labor intensity of workers is high, and the quality is unstable, but the use is most common.

2. Digital polishing machine

Digital control, semi-automatic polishing, small size, easy to use, stable quality, good repeatability.

3. Ultrasonic polishing machine

The edges and corners will not collapse after polishing, and the accuracy of the hand model will not be affected.

Generally speaking, the polishing technology of the prototype is as follows:

(1) Mechanical grinding: mechanical grinding methods such as electric grinder disc type and vibration type.

(2) Dry grinding: the disadvantage of sandpaper grinding is that a lot of dust will be produced during the operation, which will affect the environmental health.

(3) Wet grinding: sand paper dipped in water or soapy water for grinding.