Technological measures to improve machining accuracy

Technological measures to improve machining accuracy

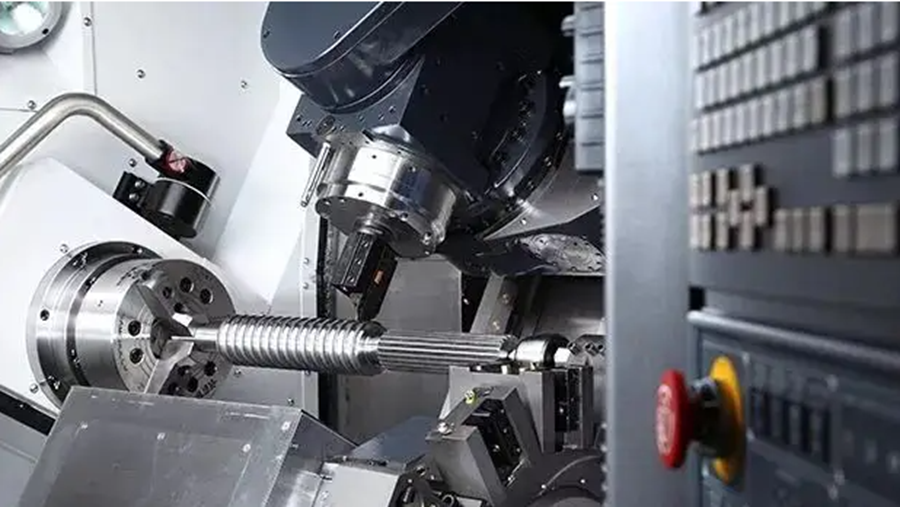

Direct error reduction method: direct error reduction is a basic method widely used in production. After finding out the main factors that cause machining errors, various technological measures can be taken to directly eliminate their effects in whole or in part.

Error compensation method: It is to artificially create a new original error to offset the original error inherent in the original process system. Thus, the machining error is reduced and the machining accuracy is improved.

Error transfer method: in essence, it transfers the geometric error, stress deformation and thermal deformation of the process system to the direction that does not affect the machining accuracy.

Error grouping: In production, the processing accuracy of this process is stable and the process capacity is sufficient, but the accuracy of the semi-finished products processed by the blank or the previous process is too low, which causes positioning error or remapping error, so the processing accuracy cannot be guaranteed. If it is required to improve the blank accuracy or the processing accuracy of the previous process, it is often uneconomical. At this time, the error grouping method can be used to divide the size of blanks (or the previous process) into n groups according to the error size. The error of each group of blanks will be reduced to 1/n of the original. Then, adjust the relative position of the tool and the workpiece or adjust the positioning element according to each group, which can greatly reduce the size dispersion range of the whole batch of workpieces. The grouping assembly method can also be used to improve the fitting accuracy of the fitting parts.