ABS, the king of Almighty in the field of plastic application

ABS material has excellent comprehensive performance, hard, shiny and easy to color. It is widely used in various fields and can be called the “king of Almighty” in the plastic industry.

1、 Introduction to ABS materials

ABS is a polymer composed of acrylonitrile a, butadiene B and styrene s. 1,3-butadiene can provide low temperature ductility and impact resistance for ABS; Acrylonitrile provides ABS with hardness, heat resistance, acid and alkali resistance and other chemical corrosion properties; Styrene can provide ABS with hardness, processing fluidity and product surface finish.

In terms of morphology, ABS is an amorphous material, which has many characteristics, such as low temperature resistance, impact resistance, low creep, excellent dimensional stability and easy processing, and has high surface hardness and good chemical resistance. By changing the proportion of the above three components, various properties of ABS can be changed. ABS is widely used as engineering plastics.

2、 Basic properties of ABS

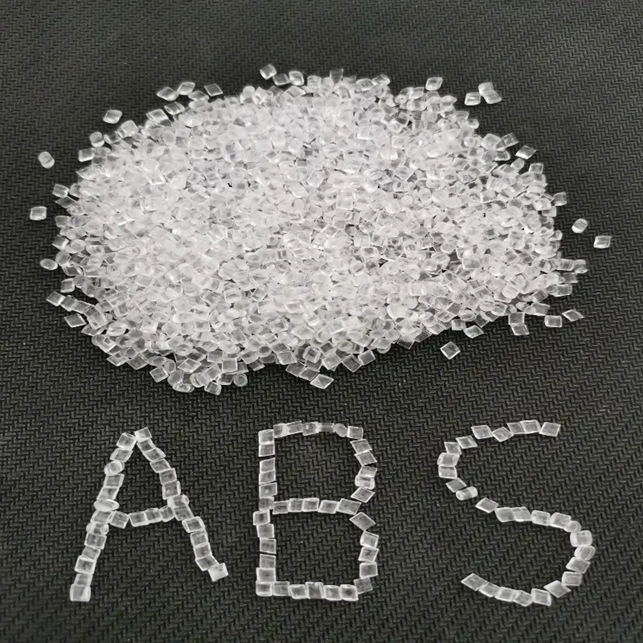

ABS raw material is light yellow or milky white granular material with certain toughness, and the density is about 1.04 ~ 1.06 g / cm3. ABS has strong corrosion resistance to acid, alkali and salt, and is resistant to organic solvent dissolution to a certain extent. It can be mixed with a variety of resins to form blends, such as PC / ABS, ABS / PVC, PA / ABS, PBT / ABS, etc., resulting in new properties and new application fields.

It has good formability in the environment of – 25 ℃ ~ 60 ℃. The processed products have a smooth surface and are easy to dye and electroplate. Therefore, it is often used in household appliance shells, toys and other daily necessities, such as the well-known “Lego building blocks”.

3、 ABS performance

ABS is non-toxic, tasteless and low water absorption. It can be made into various colors and has 90% high gloss. ABS has good adhesion with other materials, including surface printing, coating and coating treatment. The oxygen index of ABS is 18.2. It is a flammable polymer with yellow flame and black smoke. It is scorched but does not drip, and will give off a special cinnamon flavor. Adding flame retardant can make ABS become flame retardant material, which can ensure the safety and fire prevention of finished products; At the same time, low smoke during combustion reduces environmental pollution.

ABS has higher impact strength and surface hardness in a wide temperature range. The thermal deformation temperature is higher than that of PA and PVC. The critical surface tension is 34-38mn / cm, and the shrinkage is in the range of 0.4% ~ 0.8%. If reinforced by glass fiber, it can be reduced to 0.2% ~ 0.4%. The melt fluidity of ABS is better than that of PVC and PC, but worse than that of PE, PA and PS. similar to POM and hips, ABS belongs to non-Newtonian fluid and is more sensitive to shear rate.

Mechanical properties: ABS has excellent mechanical properties and excellent impact strength. It can be used at very low temperature. Even if ABS products are damaged, it is only tensile failure, not impact failure. However, the mechanical properties of ABS are greatly affected by temperature.

ABS has excellent wear resistance and oil resistance, so it can be used for bearings under medium load and speed. The creep property of ABS is larger than PSF and PC, but smaller than PA and POM. The bending strength and compressive strength are poor in plastics.

Thermal properties: ABS is an amorphous polymer with no obvious melting point, high melt viscosity, poor fluidity and weather resistance; Ultraviolet light can change the color of ABS, the thermal deformation temperature is 70-107 ℃ (about 85), and the product can be increased by about 10 ℃ after annealing.

However, ABS can still show certain toughness at – 40 ℃ and can be used for a long time in the temperature range of – 40 ℃ to 85 ℃, with a thermal decomposition temperature of more than 270 ℃.

Electrical performance: ABS has good electrical insulation and is hardly affected by temperature, humidity and frequency. It can be used in most environments.

Environmental performance: ABS is not affected by water, inorganic salts, alkali alcohols, hydrocarbon solvents and a variety of acids, but soluble in ketones, aldehydes and chlorinated hydrocarbons. Stress cracking will occur due to the erosion of glacial acetic acid and vegetable oil. ABS is easy to degrade under the action of ultraviolet light. After being placed outdoors for half a year, the impact strength decreases by half.

4、 Application of ABS

ABS has excellent performance, impact resistance, high rigidity, oil resistance, low temperature resistance, chemical corrosion resistance, electrical performance, ease of processing and low price. It is widely used in electronic and electrical appliances, instruments and meters, automobile, construction industry and other fields.