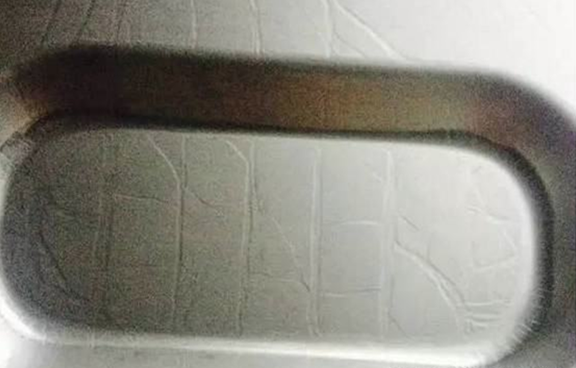

How to do stainless steel stamping wrinkle?

Cause of stainless steel wrinkling: when the metal flows inward through the tensile ring in a radial manner, the compression force may cause wrinkling, and the clamp will prevent the occurrence of such wrinkling. If the metal flows unevenly or without the support of the stretching ring, wrinkles will begin to occur. Thin materials require more fixing force than thick materials.

How to control the fixing force in stainless steel stamping process?

The fixing force of stamping parts can be controlled by many methods. First, use the fixing pad with relatively flat surface. When the metal flows under the fixing pad, the pressure will increase. If the fixing pad is designed at a slight angle, the fixing force will increase. In this way, the stamping will be more regular, but the stamping parts outside the stretching ring may wrinkle. If the flange will be cut in the future, you can not worry about this problem. The purpose of this design is to effectively control the metal flowing into the stretching ring.

Second, a punching ball can be added to the fixed pad, and a corresponding groove can be added below to further prevent the metal from flowing inward.

The above measures are taken to let the side wall wait for more stretching when necessary. Although there are ready-made parameters for the fixed force, it is usually necessary to obtain the correct fixed force through repeated tests.

The above is how to avoid the wrinkle problem of stainless steel stamping summarized by the quick screen editor. I hope it is helpful to you.