Understand various forming processes of metal materials (IV): Welding

Welding: also known as fusion, fusion is a manufacturing process and technology that joins metals or other thermoplastic materials such as plastics by heating, high temperature or high pressure.

Welding classification:

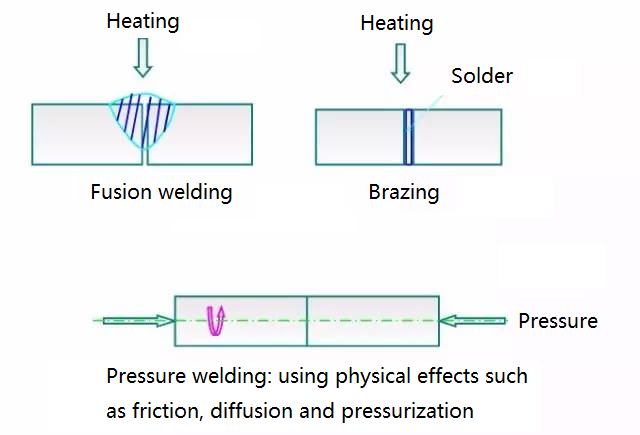

a. Fusion welding: Using a certain heat source, the connected part of the component is locally melted into liquid, and then cooled and crystallized into one, which is called fusion welding.

b. Pressure welding: Using physical effects such as friction, diffusion and pressurization to overcome the unevenness of the two connecting surfaces and remove oxide film and other pollutants is a method that the atoms on the two connecting surfaces are close to each other, so as to realize the connection under solid-state conditions.

c. Brazing: Use the material with lower melting point than the base metal as the solder, heat the weldment and solder to a temperature higher than the melting point of the solder but lower than the melting point of the base metal, fill the joint gap with the liquid solder by capillary action, melt the solder, wet the surface of the base metal, and crystallize after cooling to form metallurgical bonding.